Shandong Weifang is moving towards "new" and promotes industrial upgrading with technological innovation

"I sincerely thank the Ecological Environment Department of Weifang High-tech Zone for its assistance and advancement, which has saved us a lot of detours, saved time and costs, and promoted the rapid implementation of the project." At Shandong Inspur Huaguang Optoelectronics Co., Ltd., Deputy General Manager Wu Xianglong said happily.

It is understood that the company's third-generation semiconductor packaging and testing project is a key project in Weifang City. It belongs to a strategic emerging industry encouraged by the state. It has advanced product technology and broad market application space.

In order to promote the rapid launch of the project, the High-tech Branch of the Weifang City Ecological Environment Bureau sent specialists to take the initiative to come and intervene in advance to implement "one-on-one" precise services in project approval, indicator adjustment, etc., and guide the resolution of difficulties and blockages in the process of preparing the EIA report., greatly improving the timeliness of approval.

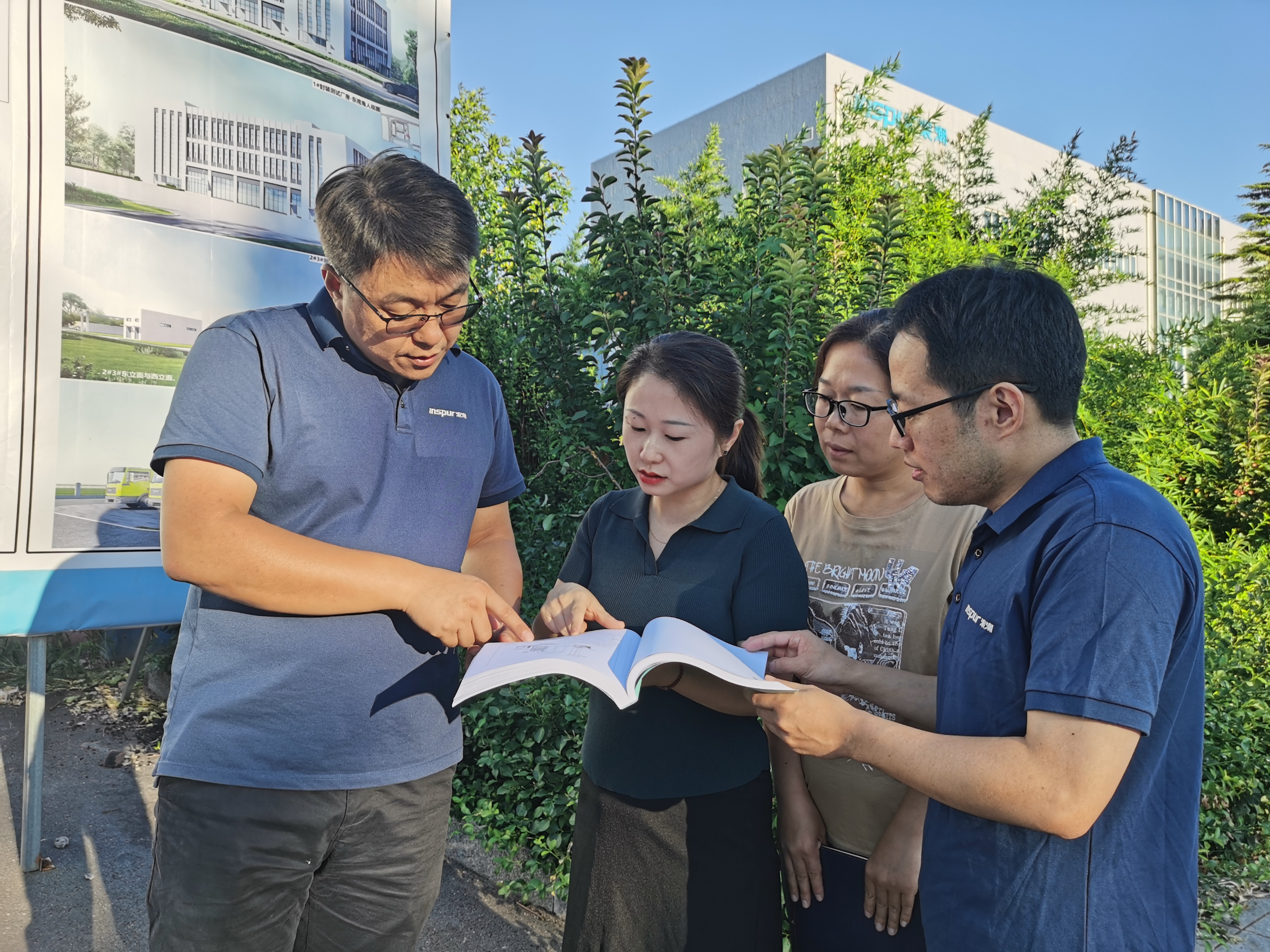

The picture shows staff from the High-tech Branch of the Weifang City Ecological Environment Bureau providing on-site assistance at Inspur Huaguang Optoelectronics Co., Ltd. to help key projects quickly implement. Photo by Dong Ruoyi

"Advanced services, rapid approval, and continuous assistance" are the magic weapon for the High-tech Branch to be a good "golden waiter" in enterprise development. They are also the key measures for the ecological environment system of Weifang City to firmly establish service thinking, promote the early implementation of large projects and put into operation, stimulate new economic momentum, and protect the development of new quality productivity.

Zou Xiaodong, Party Secretary and Director of the Ecological Environment Bureau of Weifang City, introduced that in recent years, Weifang City has insisted on promoting "new" with "new", moving towards new and green, and promoting industrial upgrading through scientific and technological innovation. The city's innovative ideas for the ecological and environmental system have successively introduced "25 measures" for the development of ecological and environmental services and "27 measures" for serving enterprises. It has pioneered the "one enterprise, one catalog, one list, one liaison" system, and "all employees support" for key projects."Full service", using the entire system to ensure the implementation of key projects, help enterprises develop green, accelerate the cultivation of new quality productivity, and lead the promotion of high-quality development and modernization.

Reshaping traditional industries and leading the way on the track of high-quality development

In the casting workshop of Shandong Luyuan Fire Protection Technology Co., Ltd., the reporter saw that the Danish DISA production line introduced by the company was running non-stop, realizing intelligent control throughout the process from unloading to unloading. The production line has jumped from the original "small stall" to the most cutting-edge casting workshop in the domestic industry. The number of workshop workers has been significantly reduced from more than 200 to more than 80, and the production efficiency has been increased from the original 300 types per hour to 580 types per hour.

The foundry industry is a traditional pillar industry in Weifang City. It is understood that there are more than 500 foundry enterprises in Weifang City, with a registered production capacity of 10.7 million tons, accounting for about 6% of the country's total. Weifang, which is responsible for such a scale in the foundry industry, is reshaping the structure of the foundry industry with the determination of "a strong man breaking his wrist" and taking the lead in achieving green, intensive and efficient development.

Fangzi District, where Luyuan Fire Protection Technology Co., Ltd. is located, is one of the major grooved pipe fitting casting industry bases in the country. In the past, industry enterprises followed the extensive development path of high energy consumption, backward equipment and technology, and low added value of products. After many inspections, Zhang Xun, the company's general manager, decided to eliminate all process equipment and spend nearly 60 million yuan to build the most advanced Danish Disa line. This seemingly bold act of emptying the family's assets, in his view, is a "strong man's broken wrist" paving the way and laying the foundation for the future development of the company.

Zhang Xun told reporters that no one understood the transformation because the price of equipment was very high. However, combined with the overall situation of the foundry industry, the immediate benefits are only short-term. If you want long-term development, you can only seek benefits from equipment process upgrades., production.

No matter how sad I am, I have to tear it down! In less than a year, a casting workshop representing the most cutting-edge technology in the domestic industry at that time rose from among the demolished factories. What transformed into nirvana was a near-qualitative leap in output and efficiency. A Danish production line alone brought an annual output value of up to 300 million yuan to the company. At that time, the qualified rate of products from similar companies was only over 80%, but Lu Yuan reached 99.9%.

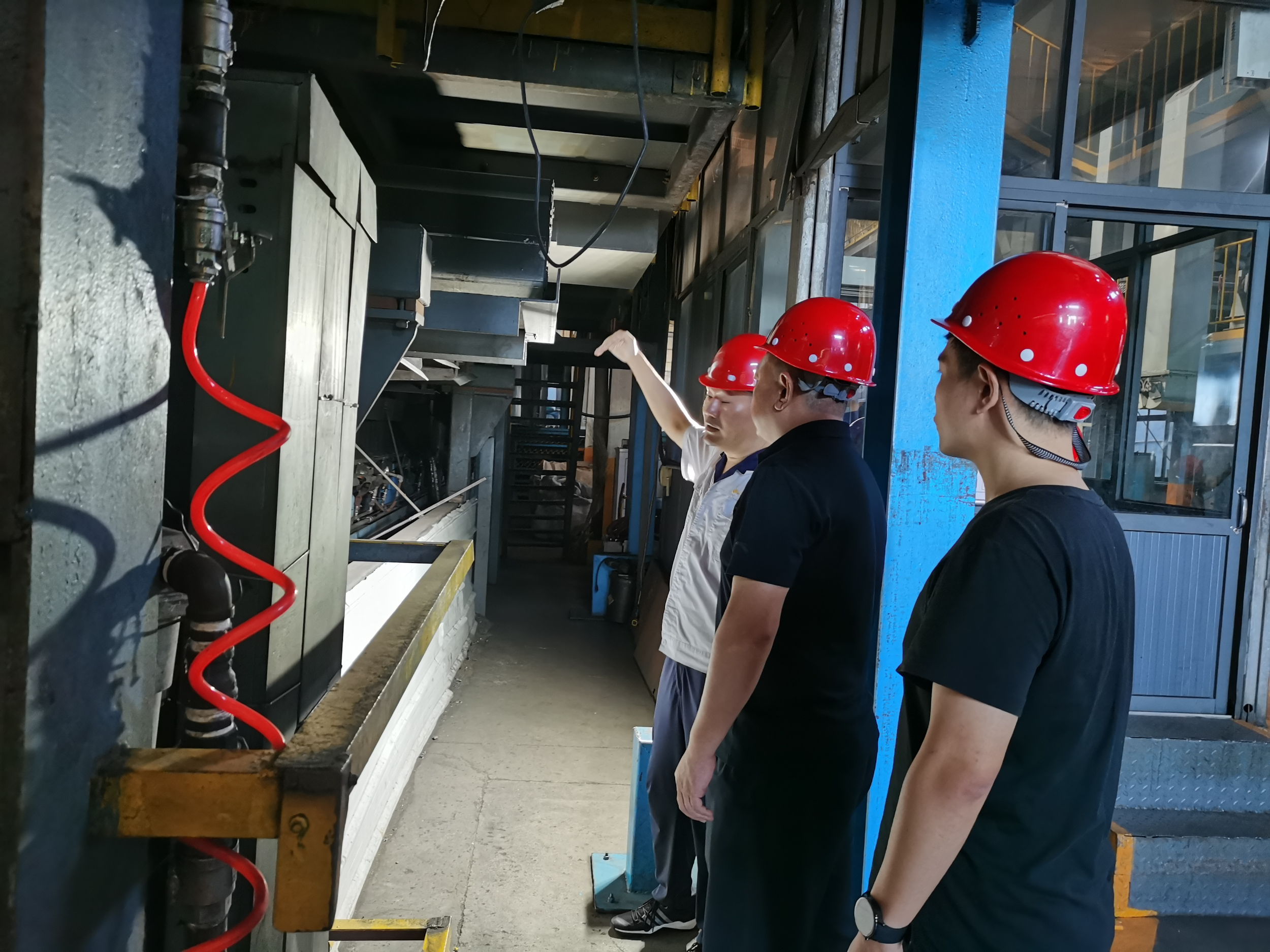

The picture shows staff from Fangzi Branch of Weifang City Ecological Environment Bureau understanding the production and operation of the company's new production line on site. Photo by Dong Ruoyi

With Lu Yuan and other industry leaders taking the lead in the successful transformation, a tough battle for the transformation and upgrading of the "green, intensive and efficient" foundry industry has been launched locally.

Fangzi District of Weifang City issued the "Implementation Opinions on Accelerating the Transformation and Upgrading of Foundry Enterprises in the Region and Promoting High-quality Development", clarifying 37 industry standards in three aspects and adopting "one enterprise, one policy." After two rounds of transformation, the number of existing enterprises has dropped to 79 today. Although it seems that there has been a subtraction on the surface, the output value efficiency has achieved an increase of more than 20% for three consecutive years. At present, the groove pipe fitting industry base centered on Fangzi District has become the main producing area of groove pipe fitting products in the country, and the traditional casting industry is on the track of high-quality development.

Taking the reform of the foundry industry in Fangzi District as a pilot, Weifang City has successively issued targeted policies such as the "Implementation Opinions on the Transformation and Upgrading of the Foundry Industry in Weifang City", taking the lead in formulating acceptance standards for the rectification and upgrading of foundry enterprises in the country, taking the lead in issuing industry transformation opinions, development plans and operating rules for production capacity replacement, and taking the lead in building a foundry industrial park, transforming "scattered, extensive and backward" into "intensive, green and efficient". Promote the comprehensive strength of foundry enterprises to rank among the top in the province and even the country, and explore and form a new model for high-quality development of the foundry industry that can be replicated and easily promoted.

In the future, Weifang City will continue to focus on high-end, intelligence, green, specialization, and park orientation, focusing on implementing eight key projects such as innovation-driven, high-quality enterprise cultivation, and digital-intelligence transformation, and strive to achieve By 2025, the city's foundry industry cluster will reach 50 billion yuan, building a national first-class green intelligent high-end foundry industry demonstration base.

Build an "environmental hospital" and gather the momentum of environmental protection industry clusters

Weichai (Anqiu) Material Forming Co., Ltd. is a casting company that produces diesel engine cylinder blocks, crankcases, cylinder heads and some hydraulic products. When the ecological environment department was carrying out navigation monitoring, the company had high navigation values from time to time. The relevant person in charge of the company was very distressed and asked Anqiu City Northern Environmental Hospital for help.

The Northern Environmental Hospital dispatched experts to conduct pulse diagnosis and diagnosis of enterprises throughout the entire process and put forward opinions and suggestions on the enterprise's unorganized exhaust gas control. Under the guidance of the Environmental Hospital, the company implemented a comprehensive closure of the pouring area based on the existing side suction in the pouring section of large and medium parts lines to effectively collect smoke and dust generated by pouring, and effectively control unorganized emissions in the area.

At present, the company's ecological and environmental management level continues to improve and has been rated as a Class A enterprise with environmental performance. It can produce independently during severely polluted weather, achieving high-level environmental protection to promote green and high-quality development of the company.

The "Environmental Hospital" model is a new strategy for Anqiu City to lead industrial development and chain construction with green development concepts, and to use energy-saving and environmental protection parks as a carrier to widely attract various elements.

In the past, Anqiu City has always been the "largest FRP production base in Jiangbei." In recent years, with the introduction of high-quality development requirements, the problems of extensive development and unsustainable development of the glass fiber reinforced plastic industry have become increasingly prominent. In order to promote the transformation and upgrading of the GRP industry, the local government made a development decision to "promote transformation and resolutely shut down". With the determination of a strong man to break his wrist, more than 900 GRP companies were reluctantly shut down.

If you close a door, you have to reopen a window. In view of the fact that the FRP industry focuses on the production of environmental protection equipment, Anqiu City insists on following the trend and being born towards "new", leading enterprises to turn into the energy conservation and environmental protection industry. The city has successfully transformed more than 200 energy conservation and environmental protection enterprises. The industry covers desulfurization and denitrification, elimination of white mist, heat and heat transfer, dust control, environmentally friendly materials, water treatment and other segments, and its market share has increased year by year.

In order to better lead the high-quality development of the energy conservation and environmental protection industry, since 2023, the Anqiu Municipal Party Committee and Municipal Government have proposed the concept of "environmental hospital" and planned to build an energy conservation and environmental protection industrial park. Through cooperation with famous "environmental doctors" such as Shandong Province Academy of Environmental Sciences, Nanjing University Environmental Planning and Design Institute, Jiangsu Yisi Testing Technology Co., Ltd., China Energy Conservation (Shandong) Energy Conservation and Environmental Protection Technology Co., Ltd., we have explored the formation of a "full chain" service system of "preliminary diagnosis → accurate detection → formulation of plans → equipment production → problem solving + daily operation and maintenance" for environmental problems, creating a good ecology and gathering highland for the development of energy conservation and environmental protection industries. Won the title of "Top Ten Characteristic Parks for Energy Conservation and Environmental Protection Industry in Shandong Province."

"Solving environmental problems with one hand and promoting the application of environmentally friendly equipment with the other hand is the direction of our environmental hospital's efforts." Jiang Xiaojin, the relevant person in charge of Anqiu Environmental Hospital, introduced.

Thanks to the diagnostic assistance of environmental hospitals, Tiantian (Shandong) Investment Holding Group Co., Ltd. has tried to carry out a large number of technological innovations and equipment updates such as magnetic suspension energy-saving motor equipment renewal and application, heat pump waste heat recovery and recycling, and process water recovery and recycling, promoting the company's power consumption indicators have been reduced by more than 20%, gas consumption indicators have been reduced by more than 50%, and water consumption indicators have been reduced by more than 40%, successfully reducing the burden on the road of energy reduction. Lead the industrial chain to make great strides towards new productivity.

Shandong Shengbao Group was born out of a glass fiber reinforced plastic products enterprise. Relying on the environmental management technical support of environmental hospitals, Shandong Shengbao Group has rapidly expanded its industrial module and accelerated the formation of new productivity in the field of environmental protection equipment manufacturing such as flue gas desulfurization, denitrification, de-whitening, wet electrostatic precipitators (mist), bag dust collectors, and VOCs waste gas treatment, and has become a well-known green and environmentally friendly manufacturing enterprise in China.

"Make up for whatever is missing, and wherever it is weak and strong." In this direction, Anqiu Environmental Hospital is making every effort to integrate industrial resources and technical strength, promote the simultaneous development of all factors of enterprises in the park in the fields of intelligence, technology, market, information, capital, etc., make the industrial chain bigger and stronger, and horizontally create a cluster-based industrial development new pattern.

At present, the market share of Lanxiang Environmental Technology Co., Ltd. in the park in the field of white fog elimination has exceeded 70%, and the market share of Wenrui Machinery (Shandong) Co., Ltd. for papermaking, pulping, washing, bleaching and alkali recovery equipment has exceeded 75%. Tianjie, Hengke, Xuneng and other companies have unique characteristics and lead the industry. The city's energy-saving and environmental protection equipment manufacturing industry has achieved operating income of nearly 10 billion yuan and embarked on a fast lane of vigorous development.

Implement the "double carbon" strategy and "borrow light to generate gold" to turn saline-alkali land into a cornucopia

Rows of wind turbines are neatly arranged, which is spectacular; photovoltaic panels dot the vast fields, shining brightly... In the Binhai District of Weifang City, new energy industry projects are advancing one after another, and there is a surge of rapid construction and rapid development everywhere.

The picture shows the photovoltaic power generation project of Weifang Binhai Scenic Storage Smart Energy Demonstration Base. information picture

The first phase of the 300 MW photovoltaic power generation project of the Fengguang Storage Smart Energy Demonstration Base in Binhai District of Weifang City is a vivid practice for Shandong Haihua Group and other companies to implement the "double carbon" goal. It is understood that the project covers an area of about 414 hectares. Relying on the brine production area of Shandong Haihua Salt Factory, it adopts a combination of "on-board power generation + bittern production" model, which not only saves land, but also improves the utilization efficiency of saline-alkali tidal flats., and has achieved green development, achieving multiple goals at one stroke.

"The annual power generation capacity of the project can reach 400 million kWh, save about 1.33 million tons of standard coal, and reduce carbon dioxide emissions by about 3.55 million tons per year. It not only achieves the complementarity of salt and light, but also achieves leading technological level and outstanding emission reduction effects. It has a very good demonstration effect." Zhang Shaohua, Party Branch Secretary and General Manager of Shandong Binhai Energy Technology Co., Ltd. introduced.

The reporter learned that Binhai District has 480 square kilometers of sea area and 60 kilometers of coastline, with an average annual sunshine hours of 2453 hours. It has unique conditions for developing the photovoltaic wind power industry.

"Borrowing light to generate gold" turns saline-alkali land into a cornucopia. In recent years, Binhai District has insisted on developing new productive forces according to local conditions, giving full play to the advantages of solar energy and wind energy resources, accelerating the construction of wind, wind and storage integrated bases, sunshine new energy, distributed photovoltaics and other projects, and focusing on building a "green power industrial park" to drive new energy industries are gathering momentum.

At present, Binhai District has gathered a total of 10 new energy projects such as Binyang New Energy's 700 MW photovoltaic power generation, Bohai Bay Port Weifang Middle Port Distributed Wind Power, and Wind and Solar Storage Smart Energy Base. The installed capacity of 6GW has been included in the province's layout. It has initially built a full industrial chain from photovoltaic power generation, green electricity transmission, energy storage power station, to green electricity hydrogen production, hydrogen storage, hydrogen transportation, and green hydrogen refining. It is estimated that by 2026, the total output value of the region's new energy industry will reach more than 3 billion yuan, and the foundation for promoting regional high-quality development will be heavier, brighter and more complete.