The world's first 30MW pure hydrogen gas turbine rolled off the assembly line, equipped with a pure hydrogen combustion chamber independently developed by Chinese enterprises

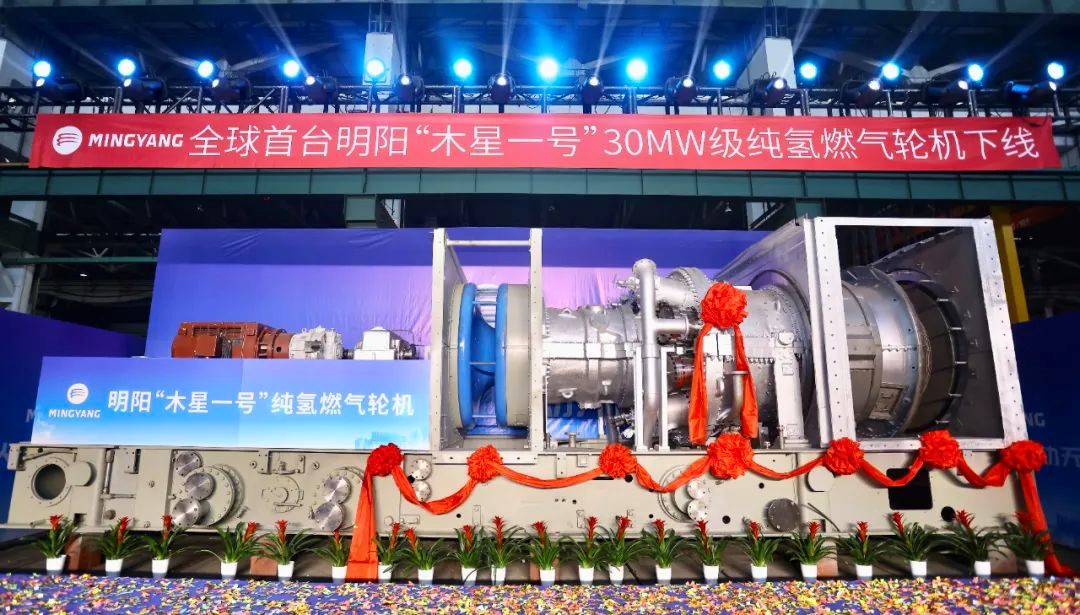

The 30MW pure hydrogen gas turbine independently developed and launched by Mingyang Hydrogen Power Technology Co., Ltd. (hereinafter referred to as Mingyang Hydrogen), a subsidiary of Mingyang Intelligence, has recently officially rolled off the production line. This gas turbine is the world's first 30MW pure hydrogen gas turbine, equipped with the "Jupiter No. 1" pure hydrogen combustion chamber independently developed by Mingyang Hydrogen Gas, which can achieve 100% pure hydrogen combustion and "zero carbon emissions" in the true sense.

The launch of pure hydrogen gas turbines is a milestone in the development of large and medium-sized gas turbines in the field of hydrogen energy in China, an important achievement in the construction of a new power system and a major breakthrough in the national "stuck neck" technology, which is of great significance for achieving the goal of "carbon neutrality" and creating a new clean energy model of "wind, solar, hydrogen storage and combustion" with international competitiveness.

Gas turbines are known as "the crown jewel of the manufacturing industry" and "the world's most difficult machinery and equipment", mainly used in power generation, distributed energy, power grid peak shaving, mobile power supply, long-distance pipeline pressurization and other fields. The reporter learned that Mingyang Hydrogen Combustion and more than 10 universities in China jointly developed the "Jupiter No. 1" pure hydrogen combustion chamber with safety, low nitrogen, wide power adjustment range and low cost in view of the three world problems of pure hydrogen gas turbine "easy tempering, easy oscillation, and high NOx (pollutant) emissions".

In order to solve the problem of new energy consumption, the demand for large-scale and long-term energy storage is becoming increasingly urgent, and the solution of "wind, solar and hydrogen storage and combustion" has received extensive attention. When there is a surplus of wind power and photovoltaic power generation, the surplus electricity will be produced by water electrolysis hydrogen production equipment, and the spherical tank hydrogen storage will be used to achieve cross-day, cross-month and cross-seasonal energy storage, and when the wind and sunlight are less, the stored green hydrogen will be used for hydrogen gas turbine power generation and heating, so as to achieve flexible resource peak shaving and valley filling, stabilize the fluctuation of new energy grid connection, and improve the safety and stability of power grid regulation.

The pure hydrogen gas turbine products that came off the production line this time were born for the "Shagehuang" area and the "big base" project. It is equipped with 10 independent "Jupiter-1" pure hydrogen combustion chambers, with a maximum hydrogen consumption of 38,000 cubic meters per hour and an annual consumption of 10,000 tons of green hydrogen, which is equivalent to the annual hydrogen consumption of 50,000 hydrogen fuel cell passenger vehicles, and an annual power generation peak regulation of nearly 200 million kilowatt hours. The launch of "Jupiter-1" can promote the development of zero-carbon cities, zero-carbon industrial parks, and zero-carbon communities, help the construction of distributed zero-carbon energy bodies in rural areas, and play an important and irreplaceable role in green peak regulation of heating, energy, and gas supply.

It is reported that since the first ignition test in May 2023, the product has become the world's largest capacity pure hydrogen gas turbine combustion chamber test, and has passed the "hydrogen and ammonia blend" combustion test, verifying the feasibility of "green hydrogen + green ammonia" mixed combustion, and has completed the full temperature, full pressure and full scale test on the domestic aero engine/gas turbine test bench, and the test was successful once.

Zhang Chuanwei, founder and chairman of Mingyang Group, said: "As the ultimate energy source for mankind, hydrogen energy is abundant, green and clean, and has a wide range of application prospects, which can realize large-scale consumption of new energy, large-scale peak regulation of the power grid, and cross-season and cross-domain energy storage applications. At a time when 97% of the world's hydrogen production comes from fossil fuels, achieving zero carbon emissions in the entire hydrogen energy industry chain is the key to industrial development, and green hydrogen is an inevitable choice. ”

Zhang Chuanwei said that the launch of Mingyang's pure hydrogen gas turbine will be a key part of the integrated solution of "wind, solar, hydrogen storage and combustion", promote the innovation and demonstration of application scenarios such as "electric hydrogen ammonia", and empower Mingyang Group to extend the green ammonia and green methanol industry chain downward by relying on hydrogen energy, and build a green "electric hydrogen ammonia" air chemical industry.

At the offline ceremony, Mingyang Intelligent signed the "Electro-Hydrogen Integration" Project Cooperation Framework Agreement with representatives of State Power Investment Yellow River Company and other enterprises. In the future, Mingyang will actively build an ecosystem, promote the R&D, manufacturing, and commercial application of pure hydrogen gas turbines, continue to give full play to the advantages of mechanisms and talents, accelerate the research and development of new energy storage technologies, and contribute wisdom and benchmarking practices to the global "carbon peak and carbon neutrality".

Tang Shuxian, academician of the Chinese Academy of Sciences, leaders of the Three Gorges Corporation, China Huadian and other units, industry experts, and investment institutions attended the offline ceremony.