Crossing the Tianshan Mountains, dressing up the "new artery" of north-south transportation in Xinjiang with green

At an altitude of more than 3000 meters, the Tianshan Shengli Tunnel of the PPP project of China Communications Construction Xinjiang Wuwei Highway is hidden among the mountains. The wind cooling in Tianshan Mountain in May was severe, but the construction site was in full swing, and a "rumbling" sound came from the tunnel. Since construction started in 2020, the roar here has lasted for five years.

The Tianshan Mountains stretch for more than 1700 kilometers from east to west, bringing abundant lakes and forest resources, and also blocking transportation exchanges between the north and south Xinjiang for a long time. In five years, the dotted lines on the design drawings of the G0711 Urumqi-Yuli Expressway Project (hereinafter referred to as the "Urumqi-Yuli Project") have become all roads, and the Urumqi-Yuli Expressway Project is expected to be shortened from the original 7 hours to about 3 hours. Among them, there are the unremitting efforts of batches of engineers, the technological support of hard rock boring machines such as the "Tianshan" and "Shengli", and the Wuwei project's persistence in protecting nature and the ecological environment like protecting eyes.

Targeted measures to reduce ecological impact

"We think it is very meaningful to protect the local ecological environment."

Starting from Urumqi and going up along the mountains along National Highway 216, the road has high mountains and deep valleys, steep slopes and sharp turns. On the side of the national highway is the Wuwei project under construction, with tall piers and stretching tunnels across the entire line.

Bridges and tunnels replace the meandering twists and turns of roads. This feature is particularly reflected in the Wuwei project. The bridge-tunnel ratio is the direct result of which is a huge amount of waste slag. Project manager Wu Xingwang told reporters that the total length of the four bridges, four tunnels, and two roadbeds he is responsible for is 13.2 kilometers, and the estimated amount of waste slag is about 1.4 million cubic meters.

"Except for nearly 500,000 cubic meters of gravel processed into gravel and reused, the remaining about 900,000 cubic meters of slag stone need to be properly processed and piled into a waste disposal yard." Wu Xingwang told reporters that the natural environment of the project is fragile and the geological conditions are complex. How to reasonably consume and dispose of the 900,000 cubic meters of waste slag and reduce the impact on the natural ecology is an ecological protection question facing the builders of the Wuwei project.

During early planning, the project focused on an open-pit mine, which was an abandoned local limestone mine with damaged original vegetation. "If the mine pit is backfilled with waste slag and finally covered with soil and planted with grass, it can not only solve the problem of waste slag disposal of the project, but also achieve ecological restoration of the abandoned mine pit." Project manager Zhao Shichun told reporters that the project and the local government reached a consensus to use the abandoned mine pit as a waste slag yard after optimization and start to be put into use in 2021.

The reporter saw in the waste slag yard that slag transporting vehicles were shuttling back and forth in the yard. The workers in the yard were busy commanding. At present, the waste slag has been piled to a height of more than 70 meters high. "After unloading the abandoned slag, the loader will immediately be leveled and compacted in layers, and the entire process will be sprinkled with water to reduce dust. After all the waste slag is transported, we will also cover the waste slag yard with cultivated soil, plant local grass seeds, and carry out ecological restoration." Project manager Zhao Ming introduced.

In fact, the design choice of construction access roads during project construction is also particularly important for ecological protection. The so-called access road refers to temporary road facilities built before the construction of the main project to solve traffic problems such as transporting construction tools, equipment and materials from off-site to the construction site.

No. 8 Cableway Bridge

Between the canyons on the east side of Tianger Peak, a 254-meter-long high-altitude cableway bridge spans the Urumqi River. This bridge is the No. 8 access road cableway bridge of the Wuwei Project. Project manager Zhang Cheng introduced that the main line of the project is laid along the opposite mountain, separated by the Urumqi River in the middle, and there are no roads in the middle to transport construction-related materials, so engineering access roads must be built. The use of cableway bridges can reduce the damage to surface vegetation and avoid affecting the ecological environment of the Tianshan National Forest Park Reserve where it is located.

Cableway bridges are extremely rare as construction roads in Xinjiang's highway industry. Project manager Cui Weiguo said frankly that the high cost of the cableway bridge is the main reason. "The cost of cableway bridges is 3-4 times that of traditional concrete bridges. Although our access road cableway bridge is expensive, it protects the local ecological environment and we think it is very meaningful." Cui Weiguo said.

Do a good job in environmental governance for project construction

"If pollution occurs during construction, it is absolutely not advisable"

The Tianshan Shengli Tunnel has a total length of 22.13 kilometers. It is the "throat" project of the Wuwei Project and the longest highway tunnel under construction in the world. It only takes 20 minutes to drive through a tunnel after completion, but the construction period takes several years. Why?

Along the tunnel that has been dug, we move towards the inside of the huge mountain. At the forefront of construction, the hard rock boring machine is chewing on the rocks like a giant beast. Project manager Lu Zejian told reporters that the entrance end of the Tianshan Shengli Tunnel of the Wuwei Project is adjacent to the National No. 1 Glacier and National Forest Park, and is located on the bank of the Urumqi River. If pollution occurs during construction, it is absolutely not advisable.

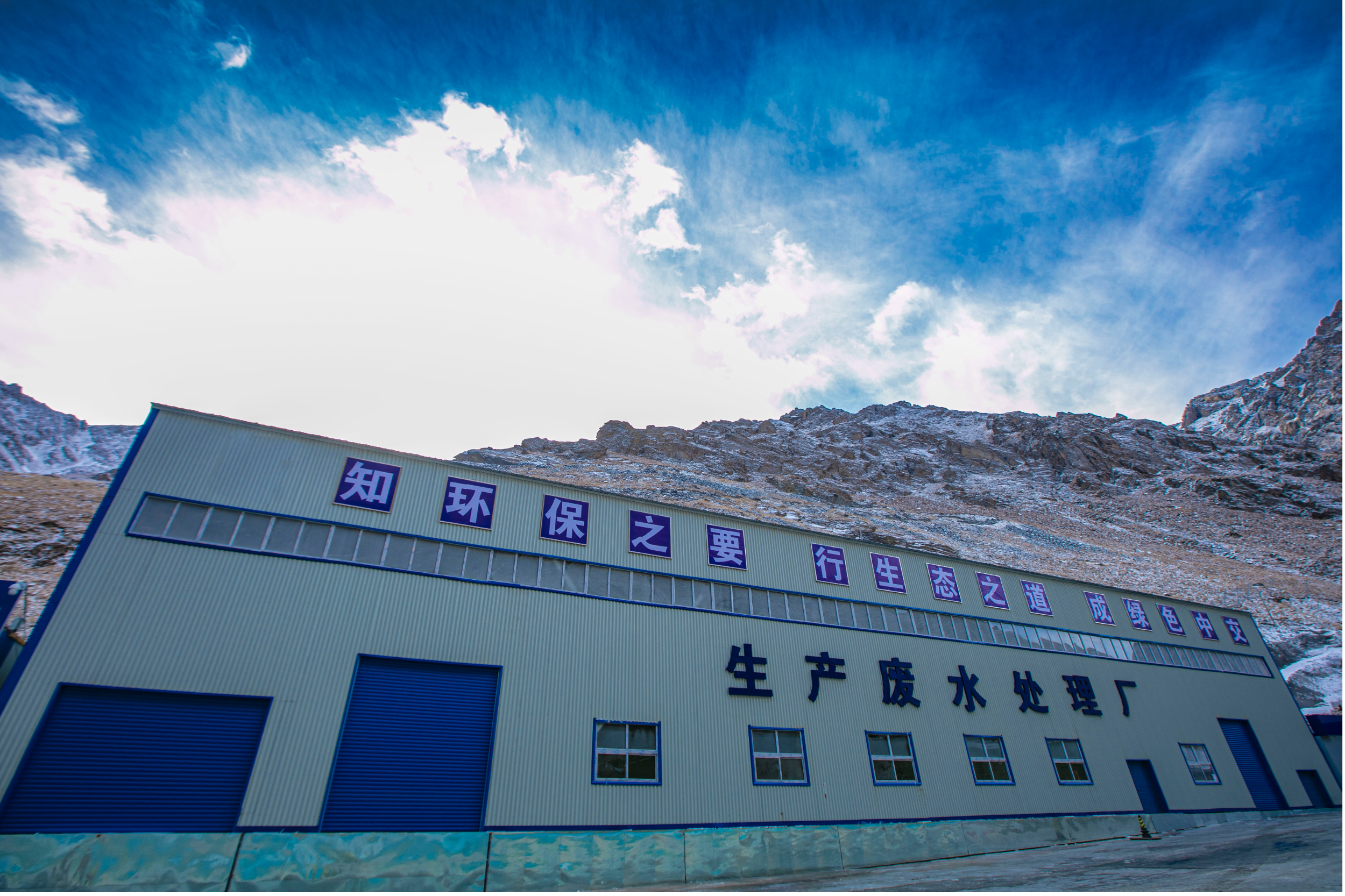

Tianshan Shengli Tunnel Entrance Production Wastewater Treatment Plant

In order to prevent the construction from affecting the local ecological environment, the project team made great efforts. Project manager Li Gang told reporters that the project has built three intelligent production wastewater treatment plants, and innovatively created a set of "cleaning and sewage diversion" collection devices to centrally treat and comprehensively utilize construction wastewater.

"'Clear 'refers to the fissure water gushing out of the Tianshan fault zone. The fissure water exists in groundwater in rock fissures and is not affected by construction." Pollution 'refers to the wastewater generated by construction, which mainly includes suspended solids, oils, ammonia nitrogen and other substances." Li Gang introduced that the collection pool in the tunnel is divided into two spatial positions: "one up and one down". The fissure water collection pool is underground and enters the central drainage pipe after settling in the collection pool; the construction wastewater collection pool is on the ground, and wastewater enters the collection pool. After settling, it enters the wastewater pipeline through the pump.

After "cleaning and diverting sewage", the production wastewater treatment plant treats construction wastewater in a centralized and targeted manner, and the treated water body is recycled for construction and life. In the factory area outside the tunnel, sprinklers that will spray water and suppress dust soon use treated wastewater in their tanks.

In the same Tianshan Shengli Tunnel, the entrance end of the Tianshan Shengli Tunnel emphasized that not a drop of wastewater should flow into the Urumqi River, while the project management personnel at the exit end of the Tianshan Shengli Tunnel told reporters about the "dust control history" of a meritorious dust removal device.

"Although this equipment is inconspicuous, it won a utility model patent in 2019 and won the 2021 China Communications Construction Micro Innovation Outstanding Achievement Award." Project manager Chen Yonggang told reporters that the tunnel at the exit end of the Tianshan Shengli Tunnel has a total length of 11.05 kilometers, and the overall concrete demand during the construction process is nearly 1.48 million cubic meters. Therefore, the concrete mixing station has a heavy workload, and the task of environmental protection and dust removal is equally arduous.

Traditional concrete mixing stations often contain dust everywhere, but such mixing methods are absolutely impossible in Tianshan, which is sensitive to the ecological environment. "Once effective collection cannot be achieved, dust will disperse everywhere, affecting fragile vegetation. Therefore, this dust removal device was developed at the beginning of the project's construction." Chen Yonggang said.

Next to the device, project manager Li Li explained to reporters in detail the mystery of dust removal: using infrared switch control, once the loader loads materials from the collecting bin, the control valve and dust removal fan start working. The fan sucks dust at the feed inlet into the pipe and then enters the dust remover for treatment. It can efficiently remove dust and reduce overall power consumption.

The dust removal effect of the "old patent" is obvious. On the day of the reporter's interview, the environmentally friendly dust removal device of this mixing station collected 2 tons of dust and filled an entire small enclosed slag truck.

Strive to be a benchmark for energy conservation and carbon reduction

"Now, green development has become the consensus of the project."

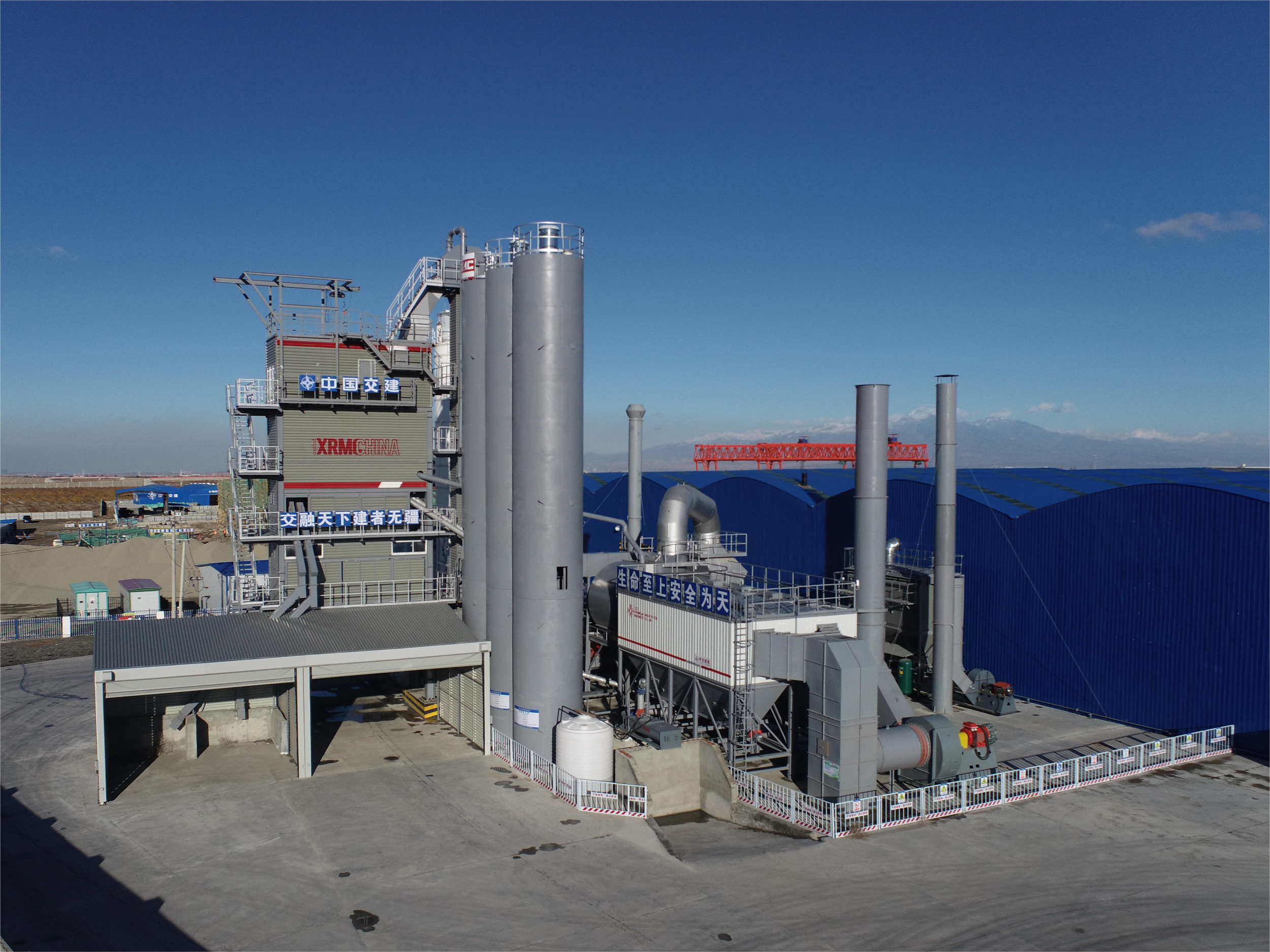

"This is an environmentally friendly asphalt station we have just built. Its biggest feature is green and energy-saving. It is expected to be put into production soon." In Yongfeng Town, Urumqi County, project manager Sui Qingtang shared the joy of welcoming the new station with reporters.

Scene pictures of asphalt station

Next to the asphalt storage tank in the station area, the reporter discovered a quite interesting thing: the originally independent asphalt heat conducting oil pipe was connected to the asphalt gravel heating device on the side through pipes. Project manager Xiao Yujie told reporters that this was intentional after technical research.

"The asphalt heat conductive tubing is used to heat the asphalt storage tank to ensure that the asphalt is in a liquid state. The asphalt gravel heating device will generate a certain amount of waste heat during operation, and normally needs to be dissipated through an air cooling device. Through equipment transformation, we connected the asphalt heat-conducting oil pipe system to the asphalt macadam heating device, and used waste heat to heat the heat-conducting oil. This not only eliminates the need for diesel combustion to heat the heat conductive pipes, but also reduces the air cooling power consumption to dissipate heat from the residual temperature device. The connection of the two devices truly reduces heat source loss and improves heat utilization." Xiao Yujie said.

Sui Qingtang introduced that the station area has also taken corresponding measures in other details to ensure energy conservation and low carbon. "Winter and spring temperatures in Xinjiang are relatively low. We use mineral wool for insulation on the exterior of drying drums, elevators, vibrating screens, thermal treatment chambers and other devices to avoid unnecessary heat source losses. Now, green development has become the consensus of the project." Sui Qingtang said.

The environmentally friendly asphalt station is just a microcosm of the Wuwei project. It encourages the research and development, promotion and application of green technologies and reduces carbon emissions and energy consumption in the entire industrial chain. The Wuwei project has been striving to set a benchmark.

As a result, batches of new technologies, new processes, new materials, and new equipment were put into use: the "ultra-short driving of long tunnels" construction process of combined construction of TBM middle pilot tunnel + double main tunnel drilling and blasting method would originally take 72 months to complete. The construction period was shortened to 52 months; the continuous belt material transportation construction technology was applied and promoted to specifically solve the energy consumption problem of long-distance transportation of crushed slag in extra-long tunnels; The developed mud-sand separation system has obtained utility model patents, realizing waste recycling and reducing material waste...

"These new changes reduce project construction costs, achieve the goals of reducing energy consumption and carbon emissions, and further promote the high-quality and green development of the Wuwei Project. They are also in line with our CCCC Group's efforts to be a leader in green and low-carbon transformation in the construction industry and key areas. The self-requirements of green and low-carbon development promoters, high-quality builders of green projects, leaders in green and low-carbon technology innovation, and contributors to the value of global ecological civilization." Cui Jingchuan, chairman and general manager of China Communications Xinjiang Transportation Investment Development Co., Ltd., said.

From deep ditches and narrow roads to running through the north and south of the Tianshan Mountains, projects are connected and cars are speeding to carry many development dreams in the north and south of Xinjiang. The Wuwei project, which pursues green, will surely pave the way for improving people's livelihood in Xinjiang.