Increasing the gold content, new content, green content and intellectual content, Taixing Economic Development Zone injects new momentum into green development

Walking in the Taixing Economic Development Zone in Taizhou City, Jiangsu Province, you are full of pipelines: more than 130 kilometers of pipe corridors have more than 10 branch pipes such as water and gas needed by enterprises in the area, and 142 companies have realized mutual raw materials, partition wall supply, and pipeline transmission.

Taixing Economic Development Zone, with a developed area of less than 60 square kilometers, has an output value exceeding 100 billion yuan, ranking among the top ten chemical parks in the country for 11 consecutive years.

The picture shows the Xinpu Chemical Administration Building.

How does Taixing Economic Development Zone follow the sustainable development path of chain development, innovative development, and green development?

Green exploration of fine chemicals

Chemical industry has always been one of Taixing's pillar industries.

The 24-kilometer Yangtze River coastline was once developed as a "gold mine" by Taixing people, which promoted local economic development, but also brought a series of environmental problems. Once upon a time, there were many "small and scattered" chemical companies here, which seriously restricted the sustainable development of this pillar industry.

How can we do a good job in environmental protection and development? The local government decided to plan and build a chemical park along the river, taking the path of concentrated chemical development and centralized pollution control.

In the huge industrial park, crisscrossing pipelines and five cracking furnaces nearly 20 stories high stand side by side. The large screen can display the production status and safe operation status of each work area of the company. In the modern monitoring room, workers can use computer operations to realize most production order sending and scheduling management...

At present, Xinpu Chemical provides chlor-alkali and olefin raw materials to 88 downstream enterprises in the park. The park amplifies the effect of the "National Circulation Transformation Demonstration Park" and forms a green development model of "small circulation within enterprises, medium circulation between enterprises, and large circulation within the park". Many strong industrial chains such as chlor-alkali, olefins, and lithium batteries have been formed, and the chemical industry has been connected. The degree of relevance has reached 78%.

Sustainable and high-quality development is inseparable from the support of large projects. The introduction of a large project will not only drive a group of enterprises, but also form an industrial cluster with competitive advantages, with points forming a "chain" and "chain" forming a face.

"When the park was established, we invited Xinpu Chemical (Taixing) Co., Ltd.(hereinafter referred to as Xinpu Chemical) to invest. In the end, we moved the other party sincerely. After this big tree was transplanted to the development zone, it quickly blossomed and blossomed and planted a green industry chain." Pan Shiquan, former director of the retired Taixing Economic Development Zone Management Committee, said with emotion.

Walking into Xinpu Chemical's factory area, the machinery of the third phase production line with an annual output of 400,000 tons of vinyl chloride is roaring. Coupled with the first and second phase production lines, the annual production capacity of vinyl chloride reaches 900,000 tons, making it the largest ethylene process vinyl chloride monomer supplier in China.

According to reports, since it settled in 1995, Xinpu Chemical has reinvested profits more than 30 consecutive times. While filling the gap in olefin raw materials, it has extended its development into downstream olefin composite materials. The total investment has expanded from the initial 30 million US dollars to the present. Nearly 3 billion US dollars.

In 2023, Xinpu Chemical will "increase its capital against the trend" by 16 billion yuan, and launch new chain-extension projects such as vinyl chloride expansion and high-performance polystyrene, and strive to become an "aircraft carrier" enterprise with sales of nearly 70 billion yuan and tax revenue exceeding 6 billion yuan. Driven by the role of chain leaders, the chain affiliated supporting enterprises "enter the chain". From liquid chemical terminals to park enterprises, from enterprises to enterprises, 80% of the products are consumed and utilized without leaving the park. The industrial chain continues to extend downward. It winds out of the most competitive and dynamic park in the country's fine chemical industry.

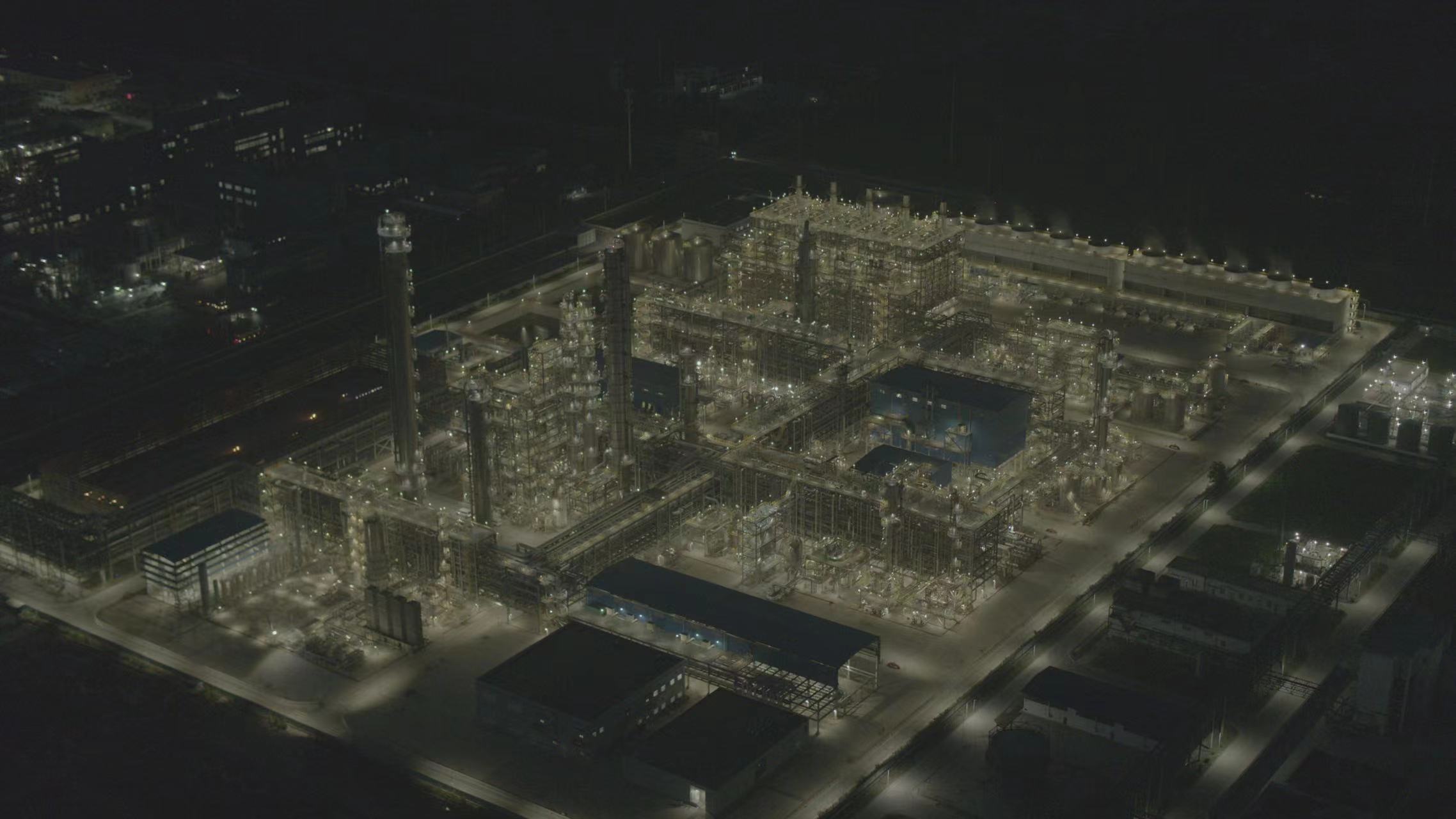

The picture shows Xinpu Chemical Olefin Plant.

Xinpu Chemical's comprehensive utilization project with an annual output of 1.1 million tons of light hydrocarbons has a total investment of 5.5 billion yuan, and can produce an annual output of 650,000 tons of ethylene, 120,000 tons of propylene, 14,500 tons of hydrogen, 45,000 tons of C4, 30,000 tons of methane, and 45,000 tons of cracked gasoline. This project has made Taixing Economic Development Zone the first chemical park in China to use clean energy to produce "big ethylene", fully achieving "self-sufficiency" and truly realizing the "upward expansion and downward extension of the industrial chain" through "chain replenishment".

Behind the vicissitudes of the ecology along the Yangtze River is the improvement of development concepts and the acceleration of high-quality development. Through today's Xinpu chemical appearance, you can touch the "golden key" of Taixing Economic Development Zone from scratch, from existence to excellence, and from small to large-focusing on filling the chain and stretching the industrial "branches and leaves".

Green development injects new momentum

In December 2023, a piece of good news came that Xinpu Chemical received the honorary certificate of "Green Factory in Jiangsu Province."

Developing new productive forces does not mean ignoring or abandoning traditional industries, but promoting industrial innovation.

Located on the bank of the Yangtze River, Xinpu Chemical has attached great importance to the protection of water resources and the surrounding ecological environment since its establishment. How to adhere to green development and reduce the footprint left by business activities on the environment?

Faced with the severe situation of increasingly tight water resources, Xinpu Chemical continues to strengthen water resources management, standardize the company's management of wastewater generation, collection and discharge, promote wastewater emission reduction, save water resources, and reduce water environment pollution.

In 2023, Xinpu Chemical used a total of 69.07 million tons of water, including 52.27 million tons of DC cooling water and 16.8 million tons of water consumption, with a reuse rate of 97.23%(excluding DC cooling water).

In recent years, Xinpu Chemical has focused on "source reduction, process prevention and control, and end treatment" and "blue sky defense battle, 263 action plan, and pollution prevention battle" as the starting point. It has invested a total of about 460 million yuan to implement thermal power boiler desulfurization and denitrification, boiler deep denitrification, storage tank unorganized waste gas treatment, wastewater treatment facilities upgrade, self-built hazardous waste utilization and disposal facilities and other environmental protection improvement projects to achieve COD, sulfur dioxide, nitrogen oxides, Emissions of major pollutants such as smoke and dust have dropped significantly.

In terms of wastewater reuse, in 2023, a new chlor-alkali salt-containing wastewater treatment unit will be put into use. After the salt-containing wastewater is treated, the concentrated brine generated will be reused to the chlor-alkali production line, saving 190m³ brine every day and reducing chloride ion emissions every year. The amount is 2,087.26 tons, calcium ion emissions are reduced by 47.23 tons, and magnesium ion emissions are reduced by 52.52 tons, creating a win-win situation for economy and environmental protection.

The picture shows Xinpu Chemical Olefin Plant.

In addition, Xinpu Chemical takes responsible care as its own responsibility, adheres to safe and green development, and selects advanced processes and automated equipment such as ionic membrane electrolysis technology, ethylene vinyl chloride production process, and ethylbenzyl-styrene production process, with low energy consumption and low pollution., excellent product quality. The unit energy consumption of all restricted products is better than the advanced value of the national standard. Through continuous energy-saving transformation and optimization of device operation, the unit energy consumption of the main product caustic soda has reached 297 kg of standard coal/ton, far better than the national standard advanced value of 315 kg of standard coal/ton. In 2023, Xinpu Chemical completed a total of 8 energy-saving projects, saving 14,000 tons of standard coal and reducing carbon dioxide emissions by 37,000 tons.

At the same time, Xinpu Chemical uses capital as the link, market as its value orientation, and technological innovation as its support to integrate resources, optimize product structure, and gradually eliminate products with high energy consumption and low added value. From 2005 to 2020, 7 units including aniline units, chlorobenzene units, nitrochlorobenzene units, solid caustic soda units, and first to third phases of caustic soda were phased out. Comprehensively implement clean production and actively explore low-carbon, green and high-quality development paths.

Xinpu Chemical is a microcosm of the high-quality development of Taixing Economic Development Zone.

Following the principle of "reduction, reuse, and resource utilization", Taixing Economic Development Zone has established and improved the "three-level circulation" development model of small enterprise circulation, medium industry circulation, and large park circulation to continuously improve resource utilization efficiency. At present, 100% of key enterprises in Taixing Economic Development Zone have implemented cleaner production audits, and more than 90% of enterprises have met cleaner production requirements, reducing resource consumption and pollutant emissions from the source.

The current Taixing Economic Development Zone focuses on industrial green and low-carbon development, eliminates backward production capacity in accordance with laws and regulations, accelerates the construction of a green manufacturing system, and further improves the gold content, new content, and green content of the chemical industry.

According to reports, in the future, Taixing Economic Development Zone will continue to improve the development of the park and strive to create a model for the sustainable development of national chemical parks.