Develop a variety of breakthrough products in the pulp and paper industry to see how Asia-Pacific Sembo moves towards "green"

Breakthrough the monopoly technology of foreign "roof bags"; produced the first carbon-neutral white cardboard in China's pulp and paper industry; and built the world's first enterprise to reuse urban water, eliminate white and reuse flue gas waste heat.

Breakthrough the monopoly technology of foreign "roof bags"; produced the first carbon-neutral white cardboard in China's pulp and paper industry; and built the world's first enterprise to reuse urban water, eliminate white and reuse flue gas waste heat.

On June 21, the Propaganda Department of the Shandong Provincial Party Committee organized an interview activity with the theme of "Walking to the Pioneer Area to See Green, Low-Carbon, High-Quality Development" and visited Asia-Pacific Sembo, the world's leading pulp and paper integrated enterprise, to learn about this "National Green Factory"."The green, low-carbon and high-quality development path.

"Roof bags" and "degradable clothing", developing a variety of breakthrough products in the industry

The Asia-Pacific Senbo exhibition hall displays various common daily necessities in our lives, such as photocopying paper, cultural paper, hygiene products, milk packaging boxes and even clothing products, all of which are realized by artificial planted forests through pulp and paper technology. Currently, this company is China's largest producer of commercial wood pulp and roofing base paper, and it is also the largest foreign-funded enterprise and overseas Chinese enterprise with investment scale in Shandong Province. Currently, it has an annual output of 2.2 million tons of wood pulp, 600,000 tons of white cardboard, 500,000 tons of cultural paper, 150,000 tons of household paper, and 25,000 tons of lyocell fiber.

"What I have in my hand is a milk carton that is common in everyone's life. Since the liquid packaging cardboard inside needs to come into contact with food or medicine, the production process requirements of raw materials are very strict. I am a noble among packaging cardboard." According to Xu Guangli, director of corporate information of Asia-Pacific Sembo (Shandong) Pulp and Paper Co., Ltd., Asia-Pacific Sembo has developed lightweight cow bottom liquid packaging cardboard to achieve the required thickness and stiffness with a lower basis weight and meet the box packaging performance. Under the same paper forming area, customers can reduce paper weight and pulp and chemical consumption by 2% to 5%, and the comprehensive technical level is at the leading level in China.

It is worth mentioning that the design of the "roof pack" on milk cartons used to be a foreign monopoly technology. After Asia-Pacific Sembo made a technological breakthrough, it has now become the company with the largest market share of the domestic milk carton roof pack base paper.

In addition, the lyocell fiber developed by the company is also very eye-catching as a key project for the conversion of old and new kinetic energy. "Lysel fiber is called 'cotton growing on trees', and clothing made from it can be degraded after being thrown into the soil for 55 days." Xu Guangli said that Lyocell fiber is a product mainly developed by Asia-Pacific Sembo, mainly made of degradable and skin-friendly materials. It performs well in terms of comfort, elasticity and sweat absorption, and is especially suitable for women and infants. The project was put into operation in 2020 and represents an important direction for the development of the fiber industry.

Clothes made of lyocell fiber

Co-construction with cities to achieve green, circular and high-quality development

Asia-Pacific Sembo comprehensively emphasizes green environmental protection measures from eucalyptus planting to wood cutting to finished product production and papermaking. "This is the first carbon-neutral white cardboard in China's pulp and paper industry. Our company's upstream companies plant an average of 1.5 million trees every day for afforestation and carbon fixation. Pollutants such as black liquor, solid waste, and waste gas in the production process have been turned into treasure, and recycling has been basically achieved." Xu Guangli introduced that Asia-Pacific Sembo uses biomass waste to generate about 1.5 billion kilowatt-hours of electricity every year, achieving basic energy self-sufficiency. It also reduces carbon emissions by more than 3 million tons and saves 1.2 million tons of standard coal every year.

It is understood that Asia-Pacific Sembo chose Rizhao in the 1990s. Due to its proximity to the city center, symbiosis and co-construction with the city is a requirement for enterprise development. Whether it is the total investment in environmental protection or the proportion of the total investment, it has reached the same scale in the world. Among the pulp and paper factories, the company has supported a total of 7 billion yuan in environmental protection investment.

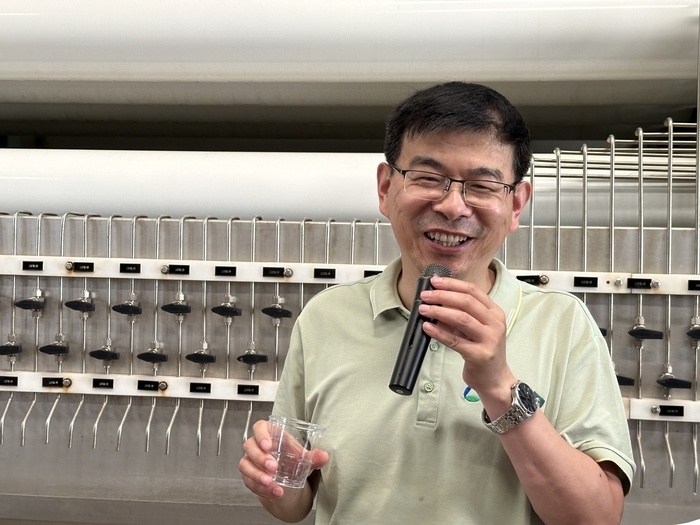

Walking into the reclaimed water reprocessing workshop, Xu Guangli introduced the company's reclaimed water treatment system and turned on the equipment to take a cup of treated water and take a sip. Xu Guangli said,"Asia-Pacific Sembo is the first enterprise in the pulp and paper industry to build urban reclaimed water treatment and reuse, with significant water conservation and emission reduction effects. This achievement has been highly praised by the Ministry of Ecology and Environment, the Ministry of Water Resources, Shandong Province and the German GIZ institution, and has been displayed and promoted as a demonstration project in the National Environmental Protection Education Center." It is reported that the project has an investment of nearly 70 million yuan and is mainly used to receive and reprocess the reclaimed water discharged from some domestic sewage treatment plants in Rizhao Urban area. It treats 40,000 tons of reclaimed water every day, which can save nearly 10 million cubic meters of water every year. At the same time, reduce pollutant emissions. The treated "new water" is used for boiler replenishment water and cooling tower replenishment water. While strengthening the utilization of water resources, the project can also achieve annual emission reductions of 370 tons of chemical oxygen demand (COD) and 40 tons of ammonia nitrogen.

In addition, Asia-Pacific Sembo has built the world's first white elimination and flue gas waste heat recycling project for pulp and paper companies, with an investment of nearly 400 million yuan, which can save 147,000 tons of standard coal every year, reduce the amount of water carried by flue gas by 881,900 tons, and reduce carbon dioxide emissions. The amount is 382,500 tons, and 286 megawatts of waste heat can be collected, providing 6 million square meters of winter heating to residents around the community. This is the first integrated energy conservation, environmental protection and waste heat utilization project in China's papermaking industry, playing a leading and demonstration role in energy conservation and emission reduction in the national and even global papermaking industry.