Series of reports: Resolving excess capacity and superimposing ultra-low emission transformation, a new round of industry "reshuffle" has begun

Following coal-fired power plants and the steel industry, the ultra-low emission transformation of the cement industry officially kicked off. At the beginning of 2024, the Ministry of Ecology and Environment and other five departments jointly issued the "Opinions on Promoting the Implementation of Ultra-low Emissions in the Cement Industry", officially finalizing the timetable for the ultra-low emission transformation of the cement industry.

Ultra-low emissions in the cement industry are the trend of the times, which can be seen from the signals released by the country in recent years, and the industry has already formed a consensus. However, it coincides with the current recession of the cement industry, and ultra-low emissions are a systematic project, which requires a lot of investment, and enterprises are facing a lot of pressure.

Industry analysts pointed out that in the context of the era of pollution reduction and carbon reduction, multiple factors are promoting the cement industry to open a new round of "reshuffle" by resolving excess capacity and superimposing ultra-low emission transformation.

Is it in or out

China is the world's largest cement producer, and China's cement output has been ranking first in the world since 1985. As an important basic industry of the national economy, the cement industry has produced a large number of pollutants while driving economic and social development.

According to the data, the cement industry is the third largest industry in China's main air pollutants and carbon dioxide emissions, with sulfur dioxide, nitrogen oxides and particulate matter emissions accounting for 5.6%, 17.1% and 19.3% of the country's industrial emissions respectively, and carbon dioxide emissions accounting for about 13% of the country's emissions.

At the beginning of 2024, a document related to the high-quality development of the cement industry was issued. The Ministry of Ecology and Environment, the National Development and Reform Commission, the Ministry of Industry and Information Technology, the Ministry of Finance, and the Ministry of Transport jointly issued the "Opinions on Promoting the Implementation of Ultra-low Emissions in the Cement Industry" (hereinafter referred to as the "Opinions"), aiming to improve the level of air pollution control in the whole process and process of the cement industry, and promote the green and low-carbon transformation and upgrading of the industry.

Regarding the implementation of ultra-low emission transformation in the cement industry, companies in the industry are not surprised. A practitioner told Environmental Economy that after the coal-fired power plants and the steel industry successively implemented ultra-low emissions, they realized that the cement industry was not far from ultra-low emission transformation, and it was only a matter of time.

In 2020, in the "Opinions on Actively Serving and Implementing the "Six Guarantees" Task and Resolutely Winning the Battle of Pollution Prevention and Control under the Premise of Normalization of Epidemic Prevention and Control" issued by the Ministry of Ecology and Environment, "research and carry out ultra-low emission transformation of the cement industry according to local conditions" was officially proposed.

In the same year, the General Office of the Ministry of Ecology and Environment (MEE) issued the Technical Guidelines for the Formulation of Emergency Emission Reduction Measures for Key Industries in Heavily Polluted Weather (2020 Revised Edition), which formally proposed the performance classification of the cement industry, but at that time it was limited to key areas.

Among them, the emission limit requirements of A-level enterprises are that the emission concentrations of particulate matter, sulfur dioxide and nitrogen oxides in the exhaust gas of cement kilns and kiln tail waste heat utilization systems are not higher than 10 mg/m3, 35 mg/m3 and 50 mg/m3 respectively, which is consistent with the limits stipulated in the just-released "Opinions". In other words, the achievement of Grade A by cement companies is equivalent to achieving ultra-low emissions.

In 2021, the "Opinions of the Central Committee of the Communist Party of China and the State Council on Deepening the Battle of Pollution Prevention and Control" proposed to promote the ultra-low emission transformation of cement industry enterprises.

In 2023, the State Council issued the Action Plan for Continuous Improvement of Air Quality, which clearly proposes to promote the ultra-low emission transformation of the cement industry with high quality.

During this period, Hebei, Henan, Anhui, Zhejiang, Shandong, Shanxi, Jiangsu and other provinces have issued local standards that are stricter than the "Emission Standards for Air Pollutants in the Cement Industry" (GB 4915-2013) or ultra-low emission transformation policies for the cement industry, which have further tightened the pollutant emission indicators.

"Still, ultra-low emissions are not a requirement. Wang Yutao, secretary-general of the China Cement Association, said in an interview with Environmental Economy: "Compliance with emissions is a legal responsibility, and ultra-low emissions are an encouragement guide." Through ultra-low emission transformation, we will set a benchmark for green development in the industry, so that cement enterprises with high environmental performance can truly develop, drive the overall transformation and upgrading of the industry, and achieve green, low-carbon and high-quality development. ”

Since ultra-low emission transformation is not a mandatory requirement, how should cement companies choose, whether to enter or exit?

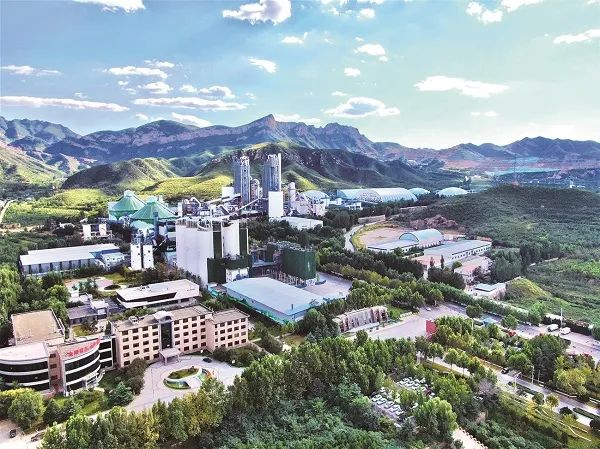

"Ultra-low emissions are the trend, which is related to the future market competitiveness of enterprises, so after the country and Hebei Province have this requirement, our company has deployed and implemented it very early. Liu Zhe, manager of the second branch of Hebei Jinyu Dingxin Cement Co., Ltd., said in an interview with "Environmental Economy".

Guo Tao, deputy director of the Metallurgical Assessment Department of the Environmental Engineering Assessment Center of the Ministry of Ecology and Environment, said in an interview with Environmental Economy: "At present, the willingness of cement companies to carry out ultra-low emission transformation is still relatively high. After so many years of atmospheric environmental governance, the cement industry to carry out ultra-low emission transformation pressure is not so great, and the national and local governments have implemented differentiated environmental management policies, and will also increase economic policy support, such as tax incentives and income tax credit preferential policies, special financial support for the atmosphere, etc., so that cement enterprises with high environmental performance can truly obtain policy dividends and solve the problem of bad money driving out good money. ”

"Judging from the survey, the cost of ultra-low emission transformation of a production line may be about 20 million yuan in terms of denitrification facilities, and the special air fund can support about eight or nine million yuan, which is a real financial support. Xu Hongxia, a senior engineer at the Metallurgical Assessment Department of the Environmental Engineering Assessment Center of the Ministry of Ecology and Environment, told the Environmental Economy that after cement companies carry out ultra-low emission transformation, they can take emission reduction measures independently after reaching the level of A-level performance grading in the cement industry.

"After the ultra-low emission transformation, our company is now rated as A-level, and there is no need to stop and limit production during the emergency emission reduction period of heavy pollution weather, which ensures the continuous operation of the enterprise, and the pollutant emissions are greatly reduced, and the cost of environmental treatment is further reduced. Liu Zhe made a rough calculation to reporters: before the ultra-low emission transformation, the ammonia consumption was 5.2 kg/ton of clinker; after the ultra-low emission transformation, the ammonia consumption dropped to about 3.5 kg/ton of clinker, according to the annual production of 5 million tons of clinker, saving 8,500 tons of ammonia, according to the price of 600 yuan per ton of ammonia, the annual cost can be saved 5.1 million yuan.

Xu Hongxia told "Environmental Economy" that some provinces also stipulate that cement companies that achieve ultra-low emissions can reduce off-peak production time, which is good for cement companies at the moment of overcapacity in the cement industry, and there are benefits in the market.

Although ultra-low emissions in the cement industry are the general trend, not all cement companies will carry out ultra-low emission transformation. According to the Catalogue for the Guidance of Industrial Structure Adjustment (2024 edition), enterprises or facilities included in the phase-out and exit plan are no longer required to implement ultra-low emission transformation. In addition, if the scale benefits of cement companies are not enough to cover the cost of ultra-low emission transformation, it cannot be ruled out that some companies will retreat in the face of difficulties, which actually means that the cement industry is reshuffling.

Funding is the biggest difficulty

At present, it is not easy for cement companies to carry out ultra-low emission transformation. The reason for making such a judgment is based on the development status of the cement industry.

According to the data released by the China Cement Association, in 2023, the total cement output in the country will be 2.023 billion tons, a year-on-year decrease of 95 million tons, and the profit of the cement industry is expected to be about 32 billion yuan, a year-on-year decrease of about 50%, the total profit of the cement industry is the lowest in 16 years, and the sales profit margin of the cement industry is far lower than the average level of industrial enterprises.

"Judging from the changes in total cement production and profits in recent years, the changes in market demand in 2022 and 2023 will only be 10% and 4.5%, while profits have fallen off a cliff, and the root of the problem is serious overcapacity. Wang Yutao told Environmental Economy that the capacity utilization rate of cement clinker in 2022 will be about 65%, and the capacity utilization rate is expected to be 59% in 2023. Therefore, with the reduction of market demand, the original market balance has been broken, cement companies began to compete for market share and "involution", vicious competition, losses continue to increase, most of the net profit of enterprises year-on-year negative growth, the efficiency of a sharp decline.

Recently, the "Outline of the 14th Five-Year Plan for National Economic and Social Development of the People's Republic of China and the Long-Range Objectives for 2035" implementation of the mid-term assessment report, in 102 major projects, 96 progress is in line with expectations, 6 are basically in line with expectations, due to the decline in local government funding capacity, some projects are not solid in the early stage of work, etc., the construction progress of some major engineering projects has been affected to a certain extent, which also directly affects the market demand for cement.

"To achieve ultra-low emissions, cement enterprises should not only transform the end treatment facilities, but also transform the whole process and the whole process, which is a systematic project, which requires enterprises to invest a lot of money, and also requires a certain transformation cycle. Wang Yutao told the "environmental economy" that in the past three years, the cement industry has entered a more difficult cycle, from the perspective of enterprises, it is a big challenge to complete the goal on schedule, and the biggest difficulty is capital.

Wang Yutao calculated an account to reporters: with a single production line of 5,000 tons / day, if the full implementation of ultra-low emission transformation requires an investment of about 100 million yuan, the operating cost of tons of clinker will increase by more than 10 yuan, and the financial pressure faced by the enterprise is very large.

Wang Yutao's statement has been recognized by enterprises. Taking Liu Zhe's company as an example, it costs more than 10 million yuan to build a material stacking shed, and more than 30 million yuan to build a selective catalytic reduction (SCR) denitrification project. "And that's just the big payout. At present, many cement companies are in a state of loss, and it has no motivation for ultra-low emission transformation. Liu Zhe told Environmental Economy.

In addition to funding, can the cement industry's ultra-low emission transformation technology keep up?

"Denitrification technology used to be the biggest technical problem faced by the cement industry to implement ultra-low emission transformation, nitrogen oxide end treatment methods include SNCR and SCR, ammonia escape problem is inevitable, but after years of research and development practice, now the technical route is basically through, and the problem of excessive ammonia escape has been basically effectively solved. Xu Hongxia told Environmental Economy.

"SCR technology is subdivided into different technical routes such as high temperature and high dust, medium temperature and medium dust, low temperature and low dust, etc., and cement companies generally choose high temperature and high dust technology routes, because the technology can operate stably and has good treatment effects. Liu Zhe believes that compared with the high-temperature and high-dust technology route, the low-temperature and low-dust technology route is definitely the best, which can not only further reduce investment and operating costs, but also achieve the lowest emission of pollutants, but the current low-temperature and low-dust technology on the market is not mature enough.

According to Gu Song, head of the cement team of the Hebei Provincial Department of Ecology and Environment, there are a variety of technical routes for the ultra-low emission transformation of the cement industry, and technology is not the bottleneck to achieve ultra-low emission transformation.

In terms of technology selection, the "Opinions" give the direction: choose mature and applicable environmental protection technologies according to factory conditions. The cement kiln is equipped with a low-nitrogen burner, adopts low-nitrogen combustion technologies such as staged combustion and fine control of oxygen content of other decomposition furnaces, adopts selective non-catalytic reduction (SNCR) and selective catalytic reduction (SCR) and other combined denitrification technologies for kiln tail exhaust gas, and adopts high-efficiency dust removal technologies such as bag type and electric bag composite type for dust removal.

In the interview, some companies reported that at this stage, they believe that there is not much pressure on the transformation of organized and unorganized ultra-low emissions, but the requirements for clean transportation are quite a headache.

According to the "Opinions", the proportion of raw fuel in and out of enterprises shall not be less than 80% of the transportation in a clean way, and the enterprises that cannot reach it shall use new energy or national VI emission standard vehicles for all automobile transportation. Enterprises in key areas use new energy vehicles for less than 80% of the clean transportation of raw fuels, and all other raw fuels are used for new energy or China VI emission standard vehicles. Priority is given to clean transportation for product transportation, and all new energy or China VI emission standard vehicles are used for automobile transportation. New energy vehicles are used for transportation in the factory. In principle, non-road mobile machinery adopts new energy.

"For cement companies with their own mines, the proportion of clean transportation is relatively easy to complete. For cement companies that do not have their own mines, it is indeed difficult to meet the requirements of the Opinions for clean transportation. In the final analysis, it is a matter of funding, because clean transportation does not involve technical bottlenecks, as long as enterprises are willing to invest, it can be solved. Xu Hongxia said.

A feast to transform the market

With the release of the Opinions, there is a clear timetable and roadmap for the ultra-low emission transformation of the cement industry. By the end of 2025, significant progress will be made in key areas, and 50% of cement clinker production capacity will be transformed, and large state-owned enterprise groups in the region will basically complete the transformation of organized and unorganized ultra-low emissions. By the end of 2028, cement clinker production enterprises in key areas will basically complete the transformation, and the country will strive to complete the transformation of 80% of the cement clinker production capacity.

In terms of organized emission indicators, in accordance with the "Emission Standard for Air Pollutants in the Cement Industry" (GB 4915-2013), the emission limits of particulate matter, sulfur dioxide and nitrogen oxides from cement kilns and kiln tail waste heat utilization systems in general areas shall not be higher than 30 mg/m3, 200 mg/m3 and 400 mg/m3 respectively, and the corresponding emission limits in key areas shall not be higher than 20 mg/m3, 100 mg/m3 and 320 mg/ respectively. cubic meters, which means that the ultra-low emission limits are reduced by 66.67%, 82.5%, 87.5% relative to the general regional emission limits, and 50%, 65% and 84.375% lower than the emission limits in key areas.

In terms of fugitive emission control measures, unorganized emission sources such as material storage, material transportation, and production process should be closed and closed under the premise of ensuring safe production, so that there is no visible smoke and dust escaping from dust production points and production facilities, and the plant area is clean and free of dust.

"In the next few years, the market demand for ultra-low emission transformation in the cement industry will continue to be released, which is a good thing for environmental protection enterprises, including desulfurization, denitrification and dust removal. Wang Yutao told "Environmental Economy" that there is a market size of about 100 billion yuan in organized ultra-low emission transformation alone.

Li Xinchuang, president of the Metallurgical Industry Planning and Research Institute, once said in an interview with "Environmental Economy" that the ultra-low emission transformation of coal-fired power plants was an example: "At first, the environmental protection enterprises in the market were also full of flowers, but after a round of 'knocking down and restarting', the number of environmental protection enterprises that finally provided ultra-low emission transformation for coal-fired power plants did not exceed 5, and there were not a few cases of environmental protection projects being overturned and restarted." ”

In Wang Yutao's view, cement enterprises should still do a good job when choosing technical routes, and choose mature, efficient and applicable environmental protection transformation technologies according to the basic conditions of different production lines to ensure long-term stability and ultra-low emissions. Some enterprises that have implemented transformation in the early stage are forced to reduce investment in environmental protection, and the effect of ultra-low emissions has regressed significantly; some enterprises have not invested in the transformation when the industry profits are better in the early stage, and now they cannot delay the ultra-low emission transformation plan because of the recession of the industry, or reduce investment and ignore the quality of the project, which will only fall into a more passive situation.

Xu Hongxia suggested that cement enterprises should first understand the existing policies, and secondly, they should go to coal-fired power plants and iron and steel enterprises to learn some advanced practices and experiences before the transformation, especially to learn the lessons of the ultra-low emission transformation of coal-fired power plants and the iron and steel industry.