Longbai Group: Abide by the green commitment and continue to save energy

As a leading enterprise in the global titanium industry, Longbai Group adheres to the concept of "green development is the background color of high-quality development" and "new quality productivity itself is green productivity", and unswervingly takes the path of green and sustainable development. We will continue to tackle energy conservation, abide by green commitments, build a green closed-loop system from park design, raw material procurement, production technology, product development, marketing model, and resource recycling, and strive to find a new path of green ecology. The Group has achieved the benign development of dual control of energy and carbon emissions, and its main products, sulfuric acid titanium dioxide and chlorinated titanium dioxide, will reach the industry benchmark level in 2023.

Energy saving, comprehensively promote energy conservation and efficiency

Energy conservation and carbon reduction are important starting points to promote carbon peak and carbon neutrality and accelerate the green transformation of development mode. The Group fully implements the policy of giving priority to conservation, strengthens energy conservation, and strives to integrate carbon peak and carbon neutrality throughout the whole process of production and operation, so as to create an environment-friendly and resource-saving "green Longbai". Since the "14th Five-Year Plan", the group has invested more than 120 million yuan, implemented more than 50 energy-saving renovation projects, achieved economic benefits of more than 9,600 yuan, and reduced carbon emissions by more than 200,000 tons. The Group has built a three-level intelligent energy consumption management and control brain platform, which implements online analysis, mining and prediction of the company's equipment status, energy efficiency load and other data, carries out accurate scheduling, fault prediction and predictive maintenance, improves energy consumption utilization efficiency and safe and stable operation level, and makes the industrial energy consumption ecology more high-end and perfect.

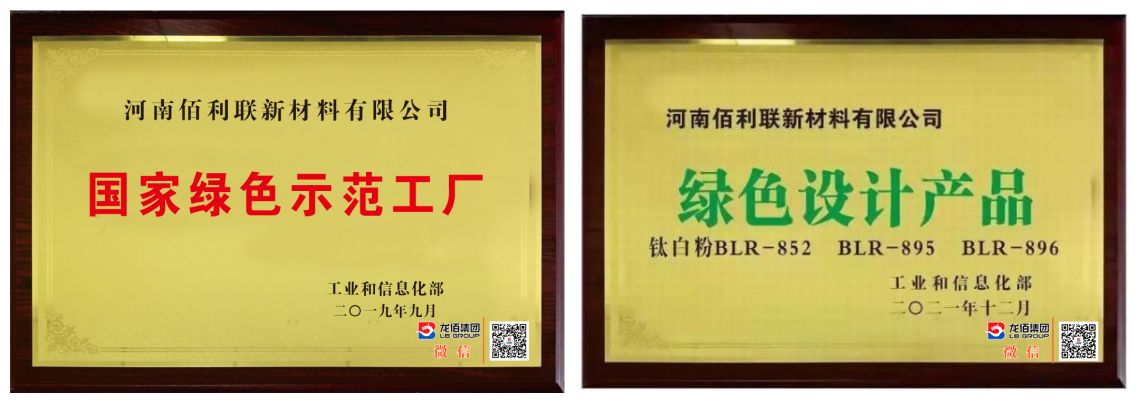

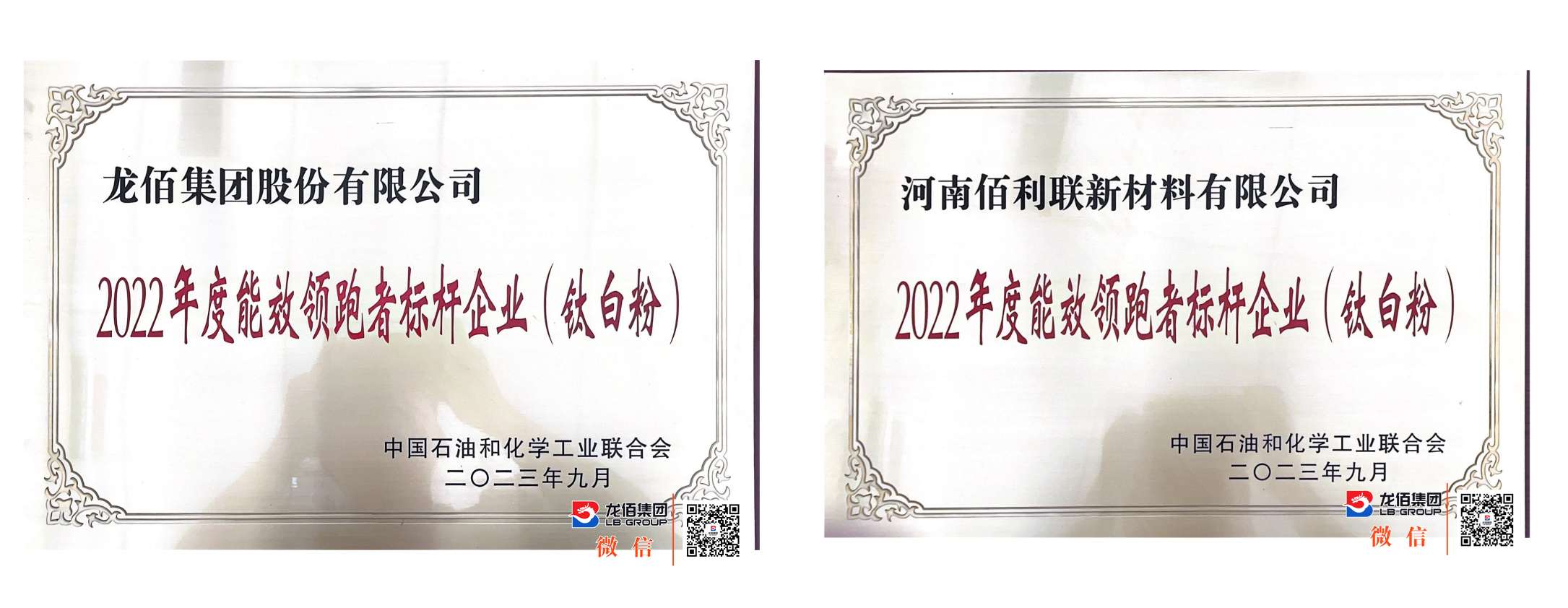

Through continuous energy conservation and carbon reduction activities, the Group's fossil energy consumption in 2023 decreased by 15% year-on-year, and clean energy consumption increased by 20% year-on-year, achieving significant results in green transformation and development. The company and its related products have won the honors of green factory and green design products issued by the Ministry of Industry and Information Technology, and have become a benchmark enterprise for energy efficiency leaders for consecutive years, realizing intensive land use, harmless raw materials, clean production, waste recycling, and low-carbon energy, and establishing a good product brand image externally.

Equipment is updated to accelerate the development of new quality productivity

In 2024, the State Council issued a notice on the Action Plan for Promoting Large-scale Equipment Renewal and Consumer Goods Trade-in, pointing out that promoting large-scale equipment renewal and consumer goods trade-in is an important measure to accelerate the construction of a new development pattern and promote high-quality development, which is beneficial to both the current and the long-term. During the "14th Five-Year Plan" period, the Group focused on intelligent updating of large-scale equipment and the implementation of equipment technological transformation and upgrading projects with energy conservation and carbon reduction, ultra-low emission, safe production, digital transformation and intelligent upgrading as important directions.

The Group plans to lay out a number of projects with leading technology, outstanding emission reduction effects, synergistic pollution reduction and carbon reduction, and obvious demonstration effects. Promote the energy-saving upgrading and transformation of key energy-using equipment such as motors, fans, pumps, compressors, transformers, heat exchangers, etc., and comprehensively improve the energy efficiency standards of equipment. Among them, more than 400 energy-saving motors have been renovated, and the comprehensive power-saving rate is more than 15%; The process hot water system is upgraded and optimized, and the traditional electric heating system is replaced by the world's most advanced and energy-efficient hot water equipment, which reduces the electricity consumption to 32% of the original hot water system, and is expected to save 2,986,800 kWh of electricity and reduce carbon by 1,570 tons per year.

resource recycling, and further promote green and low-carbon transformation

Whether it is sulfuric acid or chlorination, the titanium dioxide production process follows the requirements of green and sustainable development, energy saving, emission reduction, consumption reduction, improve resource utilization, and achieve environmental protection and low-carbon green. Regarding the utilization of waste heat in the production process of titanium dioxide, the group innovatively adopts hot air reuse and implements waste heat utilization transformation to reduce natural gas consumption by about 60 cubic meters per ton of products. At the same time, it can save nearly 40 million kilowatt-hours of electricity and reduce carbon emissions by more than 40,000 tons per year. In the process of titanium smelting and production, on the one hand, the by-product gas is recovered and utilized to save the amount of natural gas and bituminous coal; On the one hand, the surplus gas energy will be used in a distributed manner, which can generate 19,008,000 kWh of electricity per year, and the overall carbon reduction will exceed 50,000 tons/year.

Energy substitution, continue to optimize the energy consumption structure

The Group continued to strengthen the substitution of renewable energy, optimize the energy consumption structure, and transform the energy development mode. Vigorously promote the development and construction of distributed photovoltaic power generation, accelerate the pilot construction of rooftop photovoltaic development, and promote the implementation of a number of "photovoltaic +" characteristic projects. During the "14th Five-Year Plan" period, the group has invested more than 3,000 yuan to install nearly 100,000 square meters of photovoltaic modules in talent apartments and production plants. By the end of 2023, the project has generated a total of 10,920,620 kWh, saving 1,342 tons of standard coal per year and reducing carbon emissions by more than 5,000 tons per year. In terms of new energy materials, relying on the existing industrial advantages, the group has laid out the field of lithium battery materials, and has a variety of lithium battery material products such as iron phosphate, lithium iron phosphate, graphite anode, battery additives, etc., and is one of the few enterprises in China that has both lithium battery positive and negative electrode materials. Adhering to the concept of "large cycle and low cost", the company took the lead in exploring the "titanium + lithium" industrial coupling development model, which is a major industrial innovation exploration and practice combining titanium dioxide manufacturing with new energy material manufacturing.

In the future, Longbai Group will rely on the strong development advantages of the green industrial chain, continue to deepen and further improve the industrial green innovation and development system, focus on the implementation of green and low-carbon energy transformation actions, circular economy to help carbon reduction actions, green and low-carbon technology innovation and other actions, and comprehensively and systematically promote energy conservation and carbon reduction, so as to build a green new material industry group with global competition and cooperation ability and influence, and continue to write a new chapter of "Excellence, Global, Centennial" Longbai.