LONGi won two 2023 National Science and Technology Awards, related technologies can reduce water consumption and carbon emissions for silicon wafers

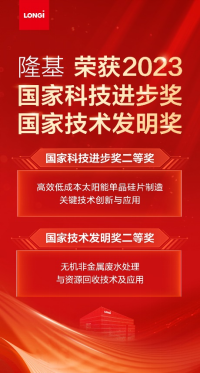

On the morning of June 24, the National Science and Technology Conference, the National Science and Technology Award Conference, and the Academician Conference of the Two Academies were grandly held in Beijing. The "Key Technology Innovation and Application of Efficient and Low-Cost Solar Single Crystal Wafer Manufacturing" project hosted by LONGi Green Energy Technology Co., Ltd.(hereinafter referred to as LONGi) won the second prize of the National Science and Technology Progress Award, and the "Inorganic Non-Metallic Wastewater Treatment and Resource Recovery Technology and Application" project in which LONGi participated also won the second prize of the National Technological Invention Award.

The selection of the 2023 National Science and Technology Award has attracted much attention in the field of science and technology. After nearly three years of precipitation, innovative projects from first-class universities, top scientific research institutes and outstanding enterprises across the country are competing on the same stage.

It is reported that the National Science and Technology Award has been established since 1984. LONGi is the first private enterprise in my country's photovoltaic field to have won the highest honor in the national science and technology field since the establishment of this award. It is also the only photovoltaic company that has won both the 2023 National Science and Technology Progress Award and the 2023 National Technological Invention Award.

It is understood that the "Innovation and Application of Key Technologies for Efficient and Low-Cost Solar Single Crystal Wafer Manufacturing" project aims at high efficiency, high quality, low cost, and solving industry resource constraints. It is the first to overcome ultra-long-cycle silicon single crystal cyclic growth under high temperature vacuum. Complete technology, meter-level thermal field heat and mass transfer refined control technology, and key technologies for the entire process of efficient argon purification and recovery. At the same time, multi-track parallel diamond wire fine plating technology and high-efficiency slicing monocrystalline silicon material cutting technology under the action of composite field forces have achieved systematic breakthroughs in core technologies for monocrystalline silicon rods and silicon wafer manufacturing.

According to the relevant person in charge of LONGi, the "Innovation and Application of Key Technologies for Efficient and Low-Cost Solar Single Crystal Wafer Manufacturing" project has perfectly solved the bottleneck problems of photovoltaic economics and the supply of supporting argon and high-purity quartz sand resources, and effectively improved the production efficiency of single crystal wafers reduces the production cost of silicon wafers, and reduces water consumption and carbon dioxide emissions during the production process, making outstanding contributions to the rapid reduction of costs in the photovoltaic industry.