"Carbon" seekers: They are deeply involved in the front line of CCUS scientific research

Recently, the State-owned Assets Supervision and Administration Commission of the State Council launched the construction of the third batch of central enterprise innovation consortiums, focusing on key areas such as strategic emerging industries and future industries, and supporting central enterprises to continue to build 3 and build 17 new innovation consortiums in the directions of industrial software, industrial mother machines, and new energy. Among them, PetroChina and China Huaneng jointly led the CCUS Innovation Consortium. Among the earliest units in my country to carry out research and development and engineering demonstration of CCUS capture technology, China Huaneng is one of them.

A reporter from China Environment News went to Huaneng Clean Energy Technology Research Institute (hereinafter referred to as Huaneng Qingenergy Institute) and interviewed his team's research and exploration in related fields.

The picture shows the CCUS team of Huaneng Qingenergy Institute.

"The value of my life and scientific research are tightly tied together."

Go north from Chaoyang District to Changping, south of the North Sixth Ring Road, the Future Science Chengdong District, which is called the "Energy Valley", and Huaneng Qingneng Institute is located here. As soon as I entered the courtyard, I saw the gurgling flowing water and the environment was quiet, comfortable and pleasant.

The reporter followed the staff to the greenhouse gas emission reduction laboratory. The first thing he saw was the purpose of Gao Shiwang's Innovation Studio-to support climate change and the "double carbon" national strategy, and promote carbon capture, utilization and storage (CCUS) technological innovation and industrial development, promote the spirit of model workers, give full play to the leading role of party members, and achieve the deep integration of party building and scientific research.

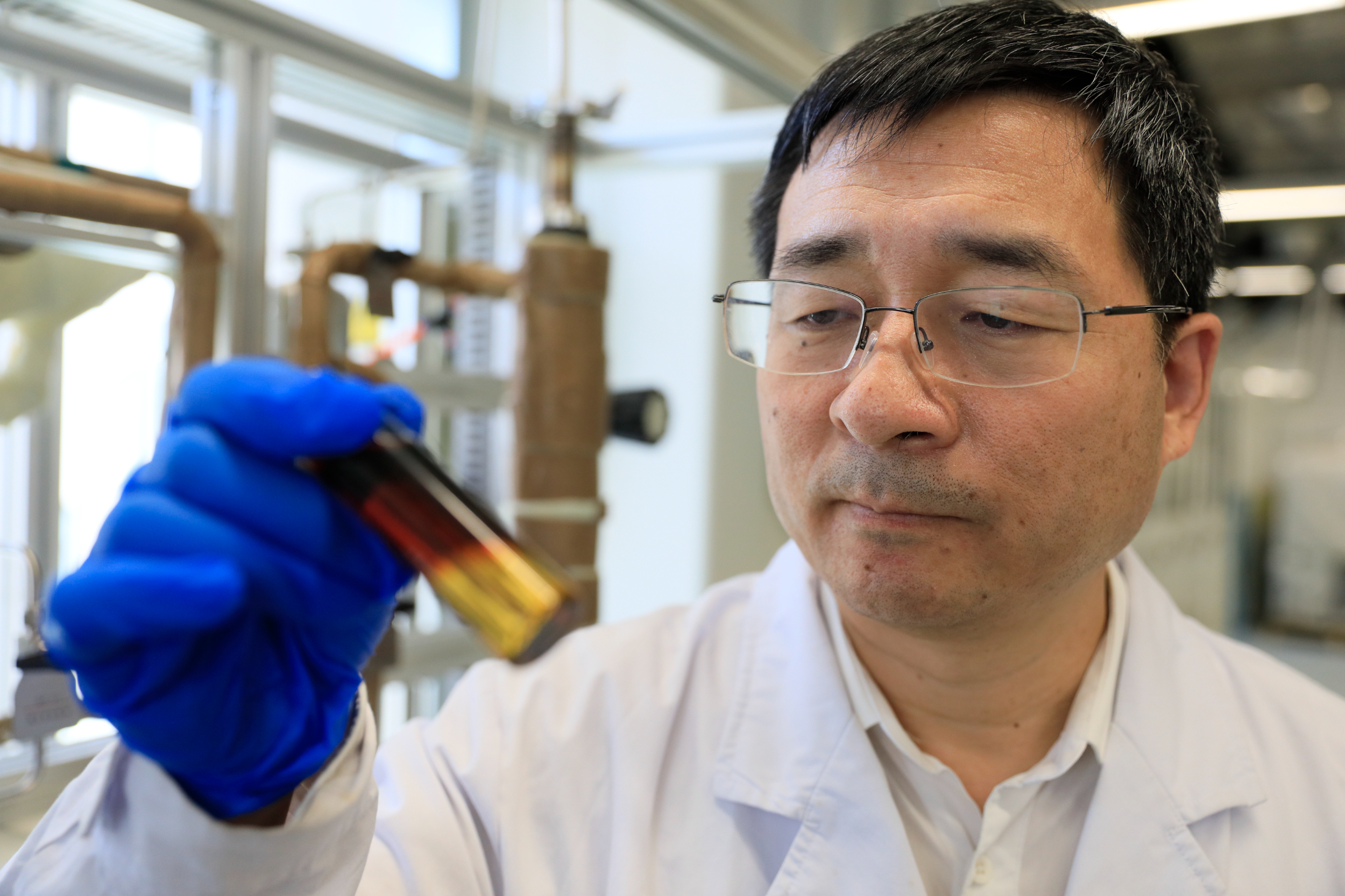

"In 1997, after graduating from Northeast Electric Power University with a master's degree in power plant thermal power engineering, I joined Huaneng Xi'an Thermal Engineering Institute. Later, I joined the coal gasification power generation 'Ninth Five-Year Scientific and Technological Research' project team led by Wei Shirang, former deputy chief engineer of Huaneng Xi'an Thermal Engineering Institute. My scientific research path at Huaneng also officially opened." Gao Shiwang, deputy chief engineer of Huaneng Qingenergy Institute, told reporters.

Talking about the scientific research and exploration in the field of CCUS over the years, Gao Shiwang said that it is full of hardships and a sense of accomplishment.

The picture shows Gao Shiwang, deputy chief engineer of Huaneng Qingenergy Institute.

"For me, choosing the front line of scientific research has tied the first button of my career. The value of my life has been closely tied to scientific research. This is the new anchor of my life." Gao Shiwang said.

In 2007, Gao Shiwang received the important task of putting into operation carbon dioxide capture devices before the Olympics and producing food-grade carbon dioxide.

"The carbon capture target set for us at that time was 3000 tons per year, which is equivalent to the CO absorbed by 160,000 trees every year.2Total amount." Gao Shiwang told reporters that the professional fields he studied were dust removal and flow field simulation, and carbon capture was just a concept in his paper for him.

"So what if I haven't met it? Foreigners can make it, but we can't? I had only one belief at that time: to overcome all difficulties, I had to get it done." Gao Shiwang said with emotion that at that time, the team had only six people, and the opening day of the Olympic Games was set as a node and the construction period was reversed.

However, before starting work, they encountered difficulties again. Due to process problems, the Australia partner could not provide drawings and technical data on time. However, at that time, there was no such major in the school, no relevant technology in the market, and no precedent in the industry. Among the data that can be found, there is too little useful information.

Therefore, after multiple considerations, the team decided to transplant the carbon capture technology of the chemical industry to the power industry.

"Due to the technical difficulty and the fact that many people did not understand the significance of this work at the time, we approached several chemical design institutes and were all rejected." Gao Shiwang told reporters,"Later, we compared more than 1000 drawings and more than 3000 data. Through continuous investigation, repeated calculations, and careful design, we successively solved technical problems such as absorbent degradation, equipment corrosion, and process optimization."

After nearly nine months of hard work, Gao Shiwang and his team finally built and put into operation my country's first set of carbon capture test demonstration device for coal-fired power plants at Huaneng Beijing Thermal Power Plant on the eve of the 2008 Beijing Olympics, filling the domestic technical gap.

After the establishment of Huaneng Qingenergy Institute in 2011, Gao Shiwang led his team to complete a number of international cooperation in the field of carbon capture and took the lead in formulating my country's first international standard in the field of carbon capture.

"We always move forward with a 'pioneering' attitude."

Over the years, my country's carbon capture technology has grown from scratch, from backwardness to transcendence, from being controlled by others to winning by others.

Currently, under the leadership of Gao Shiwang, Huaneng Qingneng Institute has formed a CCUS youth scientific research team with two national-level experts and 19 doctoral students, of which 80% are party members and doctoral students. The team has undertaken more than 30 national, provincial and ministerial key topics, won the China Patent Gold Medal, the Geneva International Invention Exhibition Gold Medal, etc., as well as 10 provincial and ministerial science and technology awards, authorized nearly 300 patents, and published more than 100 papers.

Currently, Gao Shiwang's team is responsible for building the world's largest coal-fired power plant 1.5 million tons/year CCUS demonstration project at Huaneng Longdong Energy Base. According to Fan Jinhang, the team's senior engineer responsible for carbon capture technology research and development, as the world's largest, they have encountered Many unprecedented new challenges.

"First, this project involves tackling many key core technologies such as absorbing solvents, and the development of several first sets of equipment. The key technical indicators are leading, making research and development difficult. Second, most of the current carbon capture field refers to chemical or power industry standards, and the relevant standard system is not yet complete. Third, the project collection scale is the largest in the world, and engineering design, construction and other units lack relevant project experience." Fan Jinhang introduced.

The picture shows Zhou Juan, a member of Gao Shiwang's team, measuring the depth of the borehole before shooting in 3D seismic exploration.

In addition to carbon capture, Zhou Juan, an engineer responsible for the research and development of carbon sequestration technology on Gao Shiwang's team, said that there are also some difficult problems in carbon sequestration.

According to the "China CCUS Annual Report"(2023), China's carbon emissions before 2060 will be approximately 1 billion tons/year to 2 billion tons/year, and my country's theoretical geological storage capacity will be approximately 1.21 trillion tons to 4.13 trillion tons, of which the saltwater layer storage potential accounts for more than 90%, and the storage potential is huge.

There are many factors affecting carbon sequestration. Geological factors such as storage depth, rock porosity and permeability conditions, and fault development must be considered, as well as non-geological factors such as ground conditions and population density. Of course, the core is geological factors. As long as there is sufficient underground storage space and safe storage conditions, it is possible to achieve long-term carbon dioxide emission reduction.

"There are three main steps in our exploration of geological processes suitable for carbon sequestration. The first step is to conduct site selection based on the carbon source, with the focus on evaluating the underground capacity; the second step is horizon selection, which uses three-dimensional seismic exploration, focusing on important parameters such as porosity and permeability to evaluate the suitability of the horizon; The third is to directly obtain data on underground rocks and fluids through drilling, and finally determine whether the selected location is suitable for storage." Zhou Juan told reporters.

Zhou Juan said that each of the above three steps may lead to site selection failure due to inaccurate data. There is an urgent need for research site characterization and screening, site evaluation and risk assessment technologies. At the same time, we will develop a CO2 geological storage technology system and core equipment that conforms to China's geological characteristics, optimize and reserve storage sites, and optimize CCUS-related infrastructure construction.

In addition, the team is also conducting cutting-edge exploration in other aspects.

The picture shows Sun Beiqi, a member of Gao Shiwang's team, conducting a carbon capture small-scale device experiment.

"Traditional carbon capture solvents use the interaction between organic amines and carbon dioxide to capture carbon dioxide. 60%-75% of CCUS's main costs are used in carbon capture. In order to develop more efficient carbon capture absorbents, we are currently trying to establish a high-precision database and carry out predictions through artificial intelligence to improve the performance of the absorbent and save manpower and material resources for absorbent development." Sun Beiqi, an engineer responsible for the development of carbon capture absorbents in Gao Shiwang's team, told reporters.

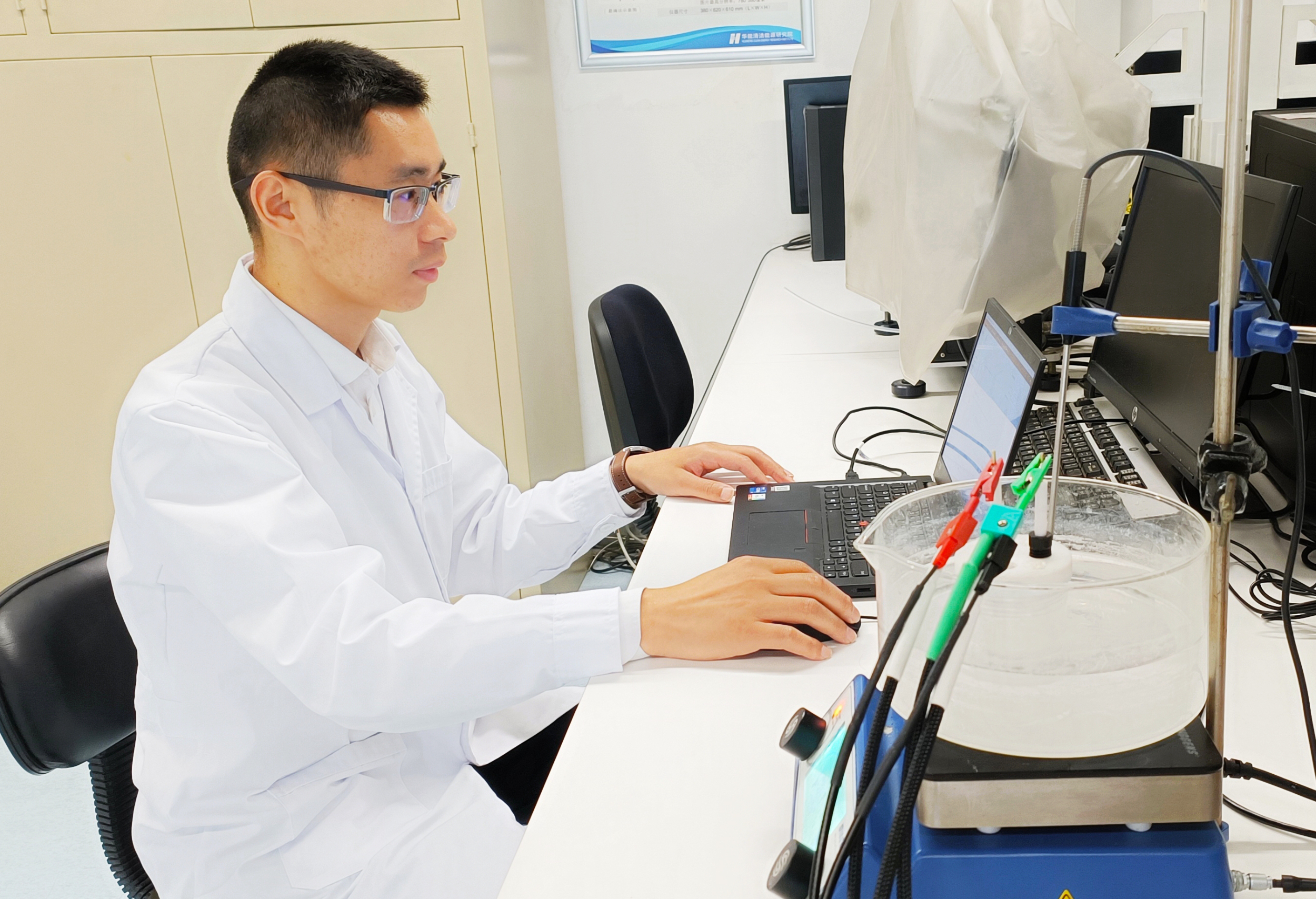

The picture shows Liu Peng, a researcher in the Materials Department of Huaneng Qingenergy Institute, conducting an electrochemical carbon capture test experiment.

"We are cooperating with Gao Shiwang's team to carry out scientific research projects related to electrochemical carbon dioxide capture and conversion and utilization. The electrochemical carbon dioxide capture project started in April this year. Different from the traditional thermal regeneration method, we chose to conduct CO through electrochemical methods.2Regeneration of absorbent rich liquor. In theory, it generates lower energy consumption than traditional thermal regeneration, and the regeneration temperature is lower, which can reduce solvent degradation and improve solvent service life." said Liu Peng, a researcher in the Materials Department of Huaneng Qingenergy Institute.

At present, with the joint efforts of the team, China Huaneng CCUS technology has achieved a series of remarkable results. Gao Shiwang said: "In the future, the team will continue to give full play to its scientific research advantages, always move forward with a 'pioneering' attitude, constantly explore the unknown, and make greater contributions to achieving my country's carbon peak and carbon neutrality goal."