The first in the country, the test was successful!

Recently, the National Energy Group Guodian Power Shengli Power Plant's large coal-fired power unit successfully tested the burning of cow dung. This test used cow dung on the Xilingol Grassland as raw material and used the existing coal-feeding system of Shengli Power Plant to blend 36.2 tons of cow dung, with a blending ratio of 13.45%. It was the country's first "cow dung blending" test. During the test period, the boiler burned steadily, the equipment operated well, and pollutant emissions reached the standard. We worked together to promote pollution reduction and carbon reduction to help low-carbon development.

▲ The picture shows the factory using coal conveying belts to transport cow dung

Shengli Power Plant thoroughly implements the National Energy Group's "136" development strategy and the "41663" overall work policy, focuses on Guodian Power's "carbon reduction, pollution reduction, green expansion, and growth" work deployment, deeply explores the potential of "carbon reduction", and accumulates new momentum for the development of conventional coal power. The factory gives full play to the regional advantages of the "Grassland Power Station", relies on the resource endowment of the four major grasslands of Xilingol, and in accordance with the principles of "one factory, one policy" and "adapting measures to local conditions", fully investigates the calorific value and mixable burnability characteristics of cow dung on the Xilingol Grassland., innovatively proposes research on carbon reduction by directly blending coal with coal power, and actively connects with the "low-carbon combustion" research team of Xi'an Jiaotong University to compare the "high volatile content and low calorific value" of lignite and "high volatile content" of cow dung. The similarities and differences between the characteristics of "high calorific value" and the characteristics of "high calorific value", organized and carried out research on blending cow dung in ultra-supercritical lignite boilers, aiming to study the application model of the entire industrial chain of "cow dung blending" from the aspects of "collection-storage-transportation-pre-processing" of cow dung/sheep dung raw materials, grinding and transportation characteristics, combustion characteristics and boilers.

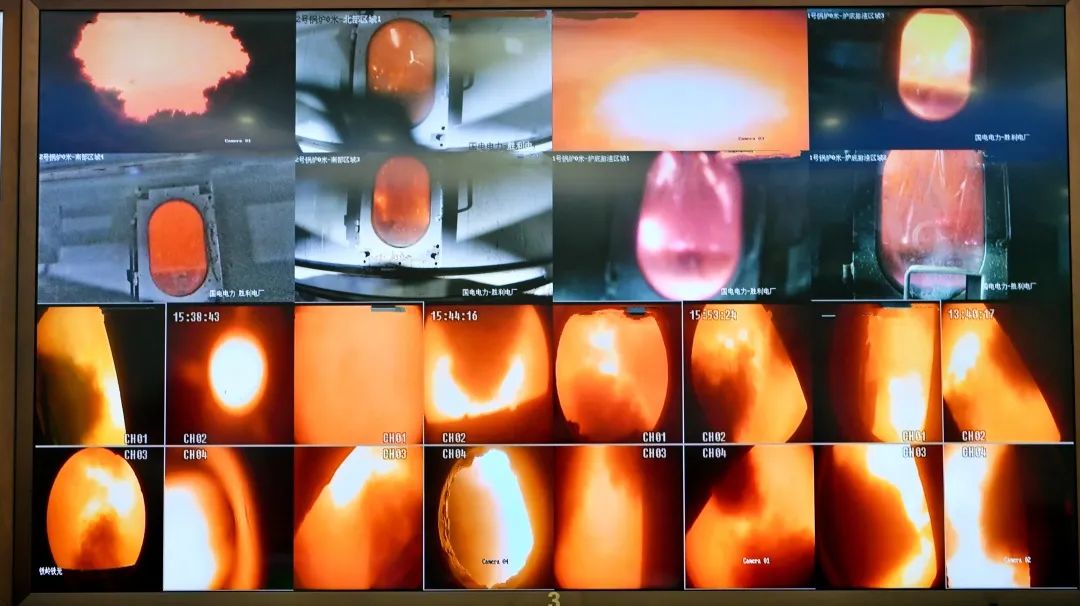

▲ The picture shows the flame combustion situation of the cow dung mixed boiler in the factory

The factory established a "biomass blending" leading group headed by the main leaders and five special working groups. Based on the principle of "safety first, scientific blending", it organized and formulated an implementation plan for cow dung blending. It organized three surveys on August 5, 8 and 10 to continue to study the key management and control points of cow dung fuel block storage and blending, boiler blending, and combustion adjustment, and coordinate safety and economic assessments. Efforts will be made to create a new path of "carbon reduction" development with grassland characteristics.

▲ The picture shows the plant's operators adjusting and monitoring the parameters of coal mills mixed with cow dung

The successful development of this blended burning test laid the foundation for the comprehensive development of Guodian Power's "biomass blended burning" work. Based on a 10% blended burning ratio of a 660-megawatt unit, it is estimated that about 200,000 tons of cow dung are blended every year., saving 85,000 tons of standard coal, reducing carbon dioxide emissions by 227,500 tons, increasing carbon emission reduction by 20 million yuan, and reducing power supply coal consumption by about 25 grams/kWh, which can create significant economic and social benefits. Contribute to the realization of the "double carbon" goal.