Wanrong Technology: Debuted at the 25th IE Expo, leading the new trend of solid waste treatment through innovation

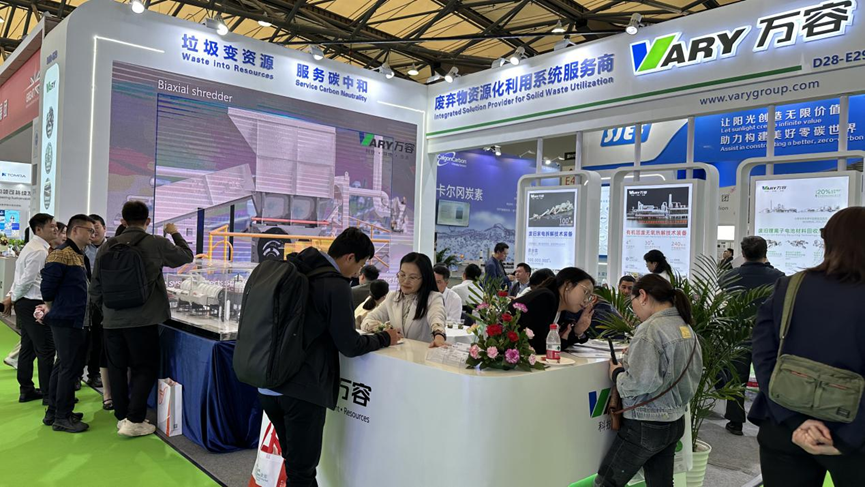

From April 18th to 20th, the 25th IE Expo China was held at the Shanghai New International Expo Center, with more than 2,400 companies from more than 20 countries around the world participating in the exhibition. Wanrong Technology made a magnificent appearance with the dismantling of waste household appliances, anaerobic pyrolysis of organic solid waste, and recycling technology and system solutions for waste lithium-ion battery materials, injecting new advantages and new impetus into the high-quality development of the environmental protection industry.

R&D and operation are integrated, and the dismantling of household appliances continues to lead

With the continuous promotion of the trade-in policy of household appliances, a large number of waste household appliances have been eliminated. How to make old household appliances "turn waste into treasure"?

The harmless recycling and resource recycling equipment of waste refrigerators developed by Wanrong Technology has been identified by the Ministry of Industry and Information Technology as "filling the domestic gap and reaching the international advanced level", and the equipment has been updated for seven generations, and has accumulated nearly 100 sets of production lines The technical background has been continuously optimized in terms of production capacity, efficiency, safety guarantee, service life, dust control, human-computer interaction, etc., and has output low-carbon, environmentally friendly and efficient waste household appliances resource recycling solutions, which have provided Haier, TCL Technology, China Recycling, Urban Development Environment, Dongjiang Environmental Protection, More than 60 domestic brand enterprises such as Beijing Enterprises City Resources, Kangwei Group, and Guangxi Materials Group, as well as global customers in Europe and Africa are ecologically empowered. At the same time, based on the integration of technology research and development and operation services, the company promotes the green development of the whole process of the home appliance industry chain, and its subsidiary, Miluo Electronic Waste Treatment Co., Ltd., as the country's first batch of home appliances "trade-in" pilot waste household appliances dismantling and treatment enterprises, has a total dismantling volume of more than 10 million units, building a recycling industry of "recycling-dismantling-waste plastic reuse". Wanrong Technology has contributed to the country's outstanding "Wanrong Power". The recycling of waste household appliances has direct economic and ecological value, and every 10,000 washing machines recycled can reduce carbon emissions by about 100 tons. Based on the total amount of household appliances dismantled by the enterprises it serves, Wanrong has reduced carbon emissions by about 1,000,000 tons for the world.

Diversified innovation, lithium battery recycling value doubled

Today, although we enjoy the benefits of science and technology, the "invisible pollution" behind it is gradually emerging. Lithium battery, as the "source of energy" of modern society, when its vitality is exhausted, how to achieve the transformation of the value of waste resources without causing pollution?

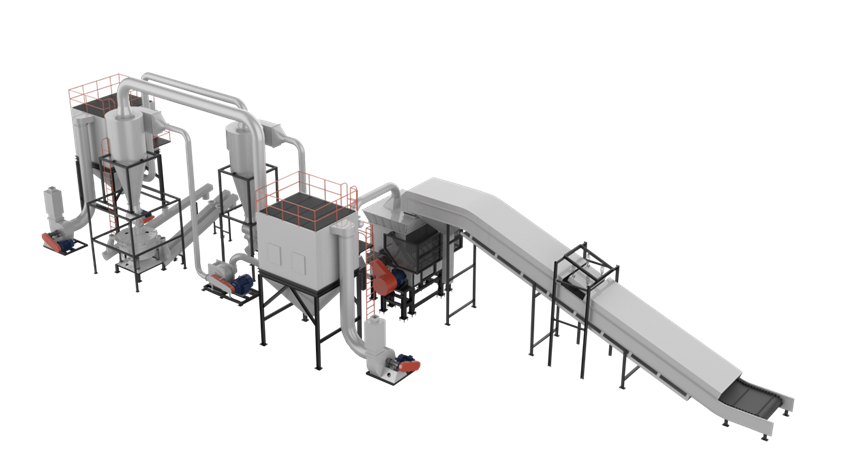

Wanrong Technology has been deeply engaged in the resource utilization of solid waste for 20 years, has rich experience in global solid waste disposal projects, combines mechanical crushing, multi-component fine sorting, and anaerobic pyrolysis equipment, and uses scientific and technological innovation to innovate and develop four waste lithium battery recycling solutions in the dual dimensions of physical and chemical recycling, giving waste lithium batteries a "second life".

After crushing and screening, two kinds of electrode powder can be obtained, of which high-purity electrode powder can be directly used as a raw material for physical repair, and the quality of ordinary electrode powder is also better than that on the market, and the recovery rate of electrode powder is high. Compared with the traditional powdering equipment, the crushing and screening process is simplified, the use of screening equipment is reduced, the maintenance cost is reduced by 50%, and the operating cost is reduced by 20%.

Based on the core single equipment of this complete set of equipment, it is integrated into the chemical recovery process to form a continuous pyrolysis comprehensive recovery integrated equipment, which is suitable for all kinds of cylindrical batteries, small prismatic batteries, pouch batteries and seriously damaged batteries, and adjusts the traditional two-stage heat treatment process to a one-stage heat treatment process to realize the direct volatilization and pyrolysis carbonization of electrolyte, separator, binder, etc., and realize copper foil, aluminum foil, The value recovery of all components of the pole powder, the gas produced by heat treatment can realize the self-sufficiency cycle of heat energy, reduce the energy consumption of the equipment, all the organic gases are incinerated at high temperature in the main furnace of heat treatment, the flue gas emission is stable and up to standard, the cost of flue gas disposal is reduced, the whole process of safe crushing is protected by inert gas, the heat treatment process is flexible and combined, the operating environment is safe and stable, and the operation and maintenance cost is reduced by 20% compared with the traditional two-stage heat treatment. In addition, for prismatic and pouch batteries, it provides fine dismantling, batch sequence anaerobic pyrolysis, and comprehensive crushing and sorting to achieve accurate separation of positive and negative electrode pieces, classified processing, and maximum value, while batch sequence oxygen-free pyrolysis can be applied to all kinds of battery industry waste (slurry, separator, etc.), ingenuity manufacturing, durable, and 100% service life. The four innovative processes have been industrialized in many projects such as Hunan and Jiangxi.

Turning crisis into opportunity, anaerobic pyrolysis helps break the situation

As the mainstream disposal method, hazardous waste incineration has the characteristics of strong inclusiveness, high efficiency and harmlessness, but its disadvantages and disadvantages are gradually emerging in practical application, and it faces many challenges such as high energy consumption, difficult flue gas emission control, high equipment investment and maintenance costs, low resource utilization rate and low economic benefits.

The anaerobic pyrolysis technology and equipment of Wanrong Technology can achieve 7*24 hours of uninterrupted and stable operation, with a wide range of adaptation, which can handle more than 30 kinds of organic wastes such as HW01, HW02, HW03, HW08, HW11, HW12, HW13, HW49, etc., and can also be properly disposed of zinc-rich paint residue, circuit board slag, waste salt, fly ash, etc., especially suitable for a wide range of large-scale comprehensive hazardous waste disposal centers, and the economic and environmental benefits generated by it are considerable.

Compared with incineration, the pyrolysis temperature is several hundred degrees Celsius lower, the energy consumption is significantly reduced, and the pyrolysis gas produced by pyrolysis can achieve self-sufficiency circulation, achieve gradient utilization of energy, and significantly increase economic benefits. The amount of flue gas produced by pyrolysis is only about 1/10 of incineration, and the fuel used for heating in the main furnace is pyrolysis gas after multi-stage purification, which effectively achieves nearly zero emission of flue gas pollutant hazard factors and significantly reduces the cost of environmental protection. At the same time, by using flexible combination seals, it ensures that the whole process is operated in an oxygen-free environment, which effectively inhibits the synthesis of dioxins. The technology and equipment have a high resource utilization rate, and can convert all kinds of organic wastes into "oil, gas and carbon", among which heavy metals are converted into stable residues under pyrolysis and solidified in pyrolysis slag. The "oil and carbon" formed by resource utilization can be used as the energy output of incineration, and can be used in coupling applications such as rotary kiln and incineration. In Shandong Hazardous Waste Disposal Center, all kinds of paint buckets, paint slag and other hazardous wastes are treated by "batch pyrolysis + crushing and sorting", and finally form iron, pyrolysis slag, pyrolysis carbon, pyrolysis oil and other products. Iron can be directly exported, pyrolysis oil is sold as crude oil, and pyrolysis carbon is used as an incineration raw material.

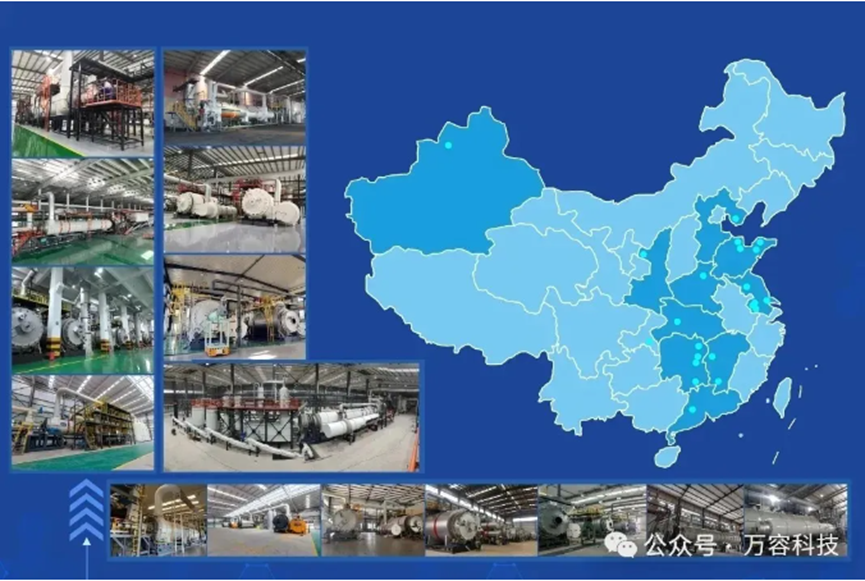

At present, Wanrong Technology's anaerobic pyrolysis technology and equipment have been successfully industrialized in dozens of solid and hazardous waste disposal projects around the world, covering paint buckets, paint residues, dye coating waste, waste organic resins, waste activated carbon, medical waste, oil sludge, sludge, waste tires, waste plastics, domestic waste RDF, etc.

Driven by digital intelligence, green environmental protection traceability and efficiency increase

In today's era, digital intelligence technology is evolving at an astonishing rate, bringing profound changes to various fields. Relying on a classification team, Wanrong Technology has successfully built a big data cloud platform for solid waste Internet of Things, and has written a new chapter with the power of digital intelligence. As an innovative technology platform, the solid waste IoT big data cloud platform has powerful functions and a wide range of application scenarios. It can not only connect the various processes of garbage classification, home appliance trade-in, home appliance dismantling and solid waste resource utilization, but also realize intelligent collection of all links from recycling to regeneration.

In Wanrong Miluo disposal base, the company has built a "triple play" Internet of Things big data cloud platform around the whole industrial chain of household appliance recycling and dismantling, providing system services such as user appointment, site management, logistics management, visual data and remote supervision, forming a closed-loop recycling system of "Internet + recycling, dismantling and recycling". In the future, the company will promote the traceability construction of PCR (Post-Consumer Recycled) formed from waste plastics from the dismantling of household appliances and scrapped automobiles, and conduct all-round tracking and monitoring of the source and flow of PCR materials to ensure their authenticity and credibility. Fortunately, European and American companies have already carried out relevant work within the scope of the pilot, which provides useful experience and reference for solving this problem.

In the past 20 years, Wanrong people have followed the footprint of resource recycling, adhered to the corporate mission of "turning garbage into resources and serving carbon neutrality", grasped the pen of innovation, pioneered the industry, made breakthroughs, and promoted the green and low-carbon development of the environmental protection industry. Looking to the future, Wanrong Technology will adhere to the market and customer demand orientation, give full play to the company's core advantages, tap the potential of new energy and environmental protection industries such as biochar preparation, automatic dismantling and pyrolysis of waste wind turbine blades, and recycling of waste photovoltaic modules, and actively promote the construction of a "zero-waste city". Wanrong firmly believes that with innovative technology, it will be able to contribute valuable to the realization of the global carbon peak and carbon neutrality goals, and jointly create a beautiful and green home.