Fengdeng Green Energy Environmental Protection: Opening up a new path for the production of green and low-carbon chemicals

On June 3, the China Petroleum and Chemical Industry Federation issued a scientific and technological achievement registration certificate to Zhejiang Fengdeng Green Energy Environmental Protection Co., Ltd.(hereinafter referred to as Fengdeng Green Energy Environmental Protection), a subsidiary of Kangenbei Group. It marks that the "Development and Application of Green and Low-Carbon Technology for Producing High-Value Chemicals from Hazardous Wastes" independently developed by Fengdeng Green Energy Environmental Protection has reached the international leading level.

In recent years, Fengdeng Green Energy Environmental Protection has focused on the corporate mission of "scientifically utilizing waste, creating green products, and jointly building a low-carbon society", focusing on technical problems such as numerous types of hazardous wastes, increased difficulty in collaborative disposal, and low-carbon emissions. The series of research and development and integration, equipment development and industrial demonstration of green and low-carbon technologies for high-value chemicals from hazardous waste have solved the technical problems of difficulty and small-scale disposal of multi-component complex hazardous wastes. Promote high-value application and green and low-carbon development of hazardous waste gasification and co-production technology. The company has successively won the titles of national-level specialized and innovative "Little Giant" Enterprise and National Green Factory.

According to Zhang Lei, President of Fengdeng, this technology uses hazardous wastes to partially or completely replace conventional fossil raw materials. Based on the principle of wet entrained flow technology, it completely converts macromolecular hydrocarbons into CO and H2 through high-temperature gasification, and then uses purification and carbon capture technologies to produce green chemicals and green energy. It is a clean, efficient green and low-carbon technology.

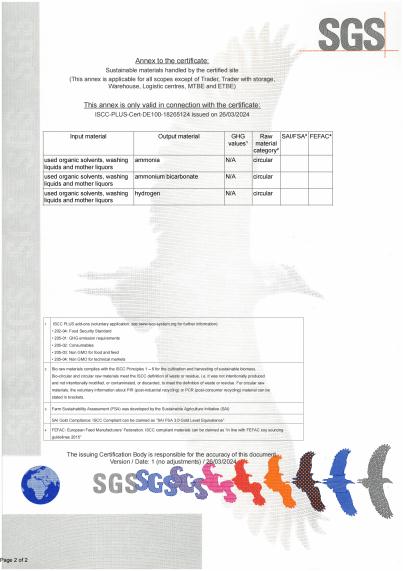

This technology can be applied to the green transformation of traditional wet fluidized bed technology and the construction of "waste-free parks" to build a circular development model. Organic solid wastes such as waste activated carbon, waste organic solvents, rectification residues, and high-salt waste liquids produced in industrial processes are all raw materials for this technology, turning waste into treasure and creating green products such as hydrogen energy (high-purity hydrogen) and lithium battery cathode materials. Hydrogen, ammonium bicarbonate, and liquid ammonia have obtained ISCC PLUS certification, which can provide sustainable green and low-carbon products for downstream enterprises. Inorganic materials are made into products such as glass slag (building materials fillers) and industrial salts, and are put back into industrial production. The application of this technology breaks through the problems of low resource utilization and high carbon emissions of traditional hazardous waste incineration and disposal technologies. It also changes the dependence of traditional gasification to chemicals technology on fossil raw materials and opens up a new path for the integrated development of environmental protection and chemical industry. path.

At present, the annual industrial application scale of "Green and Low-Carbon Technology for Producing High-Value Chemicals from Hazardous Waste" reaches 200,000 tons, serving more than 350 production and waste units. It has obtained 73 national patent authorizations, including 24 invention patents; participated in the formulation of 4 national standards and 8 group standards; the annual comprehensive utilization of hazardous waste exceeds 150,000 tons, annual standard coal saves 50,000 tons, and annual water saves 80,000 tons; The carbon emissions per ton of hazardous waste disposal are 75% lower than those of incineration, and the annual carbon emissions are reduced by more than 200,000 tons, achieving significant economic, social and environmental benefits.